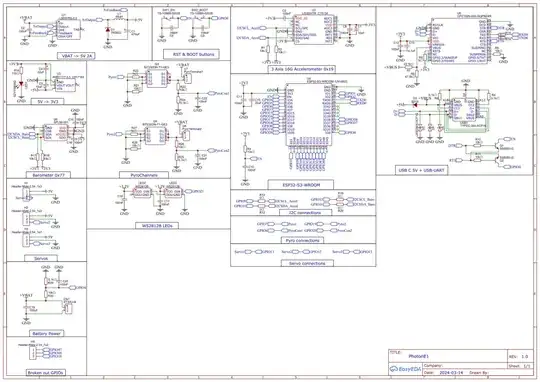

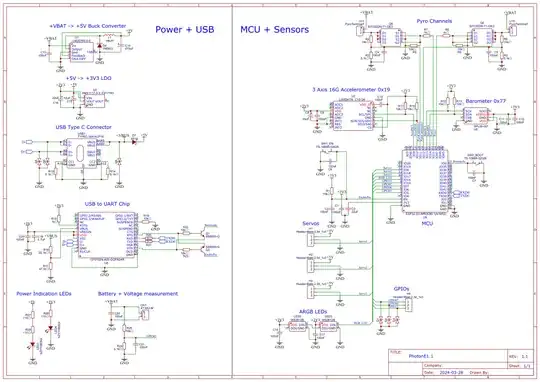

This is already much better. I would put all the power related circuits together (VBAT, 5V, power LED etc), and the USB circuit together with the UART circuit. Either connected or, at least next to each other (but then it will be obvious that you will want to connect them). But it's already OK.

Now it depends what you intend to do with the schematic. And according to what you want to do, you may want to make a second schematic, in another way.

Here the schematic is useful to understand how the circuit functions, how pins receive signals and what signals do etc. That's fine for the theoretical concept.

Now, when the schematic is to serve as a preliminary to board design, or to be used later to compare the PCB with the schematic to debug something, then you are going to face problems, maybe making mistakes, because the pins are not in their right physical order.

It sometimes makes the schematic easier to draw and to read to invert the pin orders or to reset the pins in a random order. But when you use your schematic to remember what your board is doing, to compare it with the real PCB design, check the datasheet (where pins can also be put in random orders in some circuit examples, but not in the same random order as yours), then you will run into troubles and lose time.

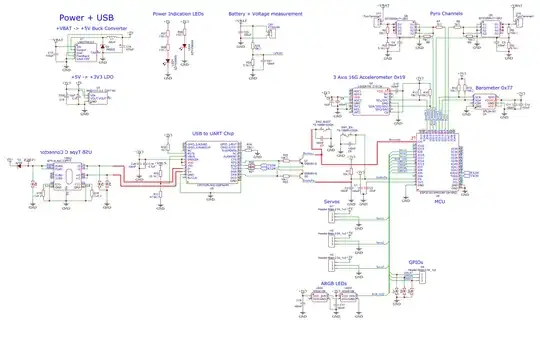

A second schematic where pins are in their original order and where everything is connected could be useful prior to design the PCB. It will help you place and rotate the components already in a rational way, visually closer to the real PCB while still having all the informations about the circuitry. It's not possible to make a schematic identical to the PCB, because you always rotate or move something to reduce trace lengths and so on, but at least, you can have intuitive similarities. When, 5 years later, you will look at your PCB and at the schematic next to each other, you will remember what does what easily, and won't lose half an hour scratching your head.