I have run into the same problem described here and here, when I added diode to electromagnet. Basically, the magnet still holds with about 20kg force several minutes after removing power. The mechanical solution of leaving air gap or adding a "peel-off" spring is not plausible due to design constraints. So, I need a snubber circuit that will protect relay contacts why still de-energize the magnet rapidly.

While looking for the solution I've stumbled upon this answer, listing many possible methods. Not having any experience with powerful electromagnets I can't decide which one would be the best for this particular setup (24V 14W magnet, 30V 10A SRD-05VDC-SL-C relay).

At this moment I am leaning towards either rectifier + zener or RC + MOV combination. Any advice, please?

UPDATE

I've confirmed that the problem is residual magnetization, not back EMF, just as @DKNguyen and others suggested. After disconnecting power I also disconnected diode and the magnet was still holding. Apparently the initial experiment without diode was done with heavy (~200kg) load that was enough to hide the magnetization.

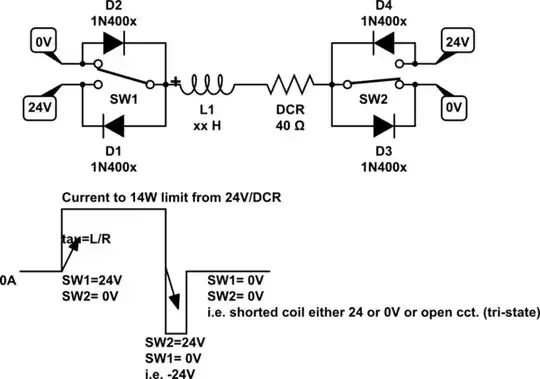

So, I am going with RC snubber, hoping that oscillations will provide sufficient demagnetizing effect. Maybe combined with MOV if initial amplitude is too high.

Note that if the problem is relay contacts sticking, that particular individual relay is probably forever prone to sticking and that simply adding a snubber may not improve the situation without changing the relay for a fresh one. The sticking is caused by arc corrosion make the contacts very high friction which remains even after you add a snubber.

– DKNguyen Apr 30 '22 at 16:25