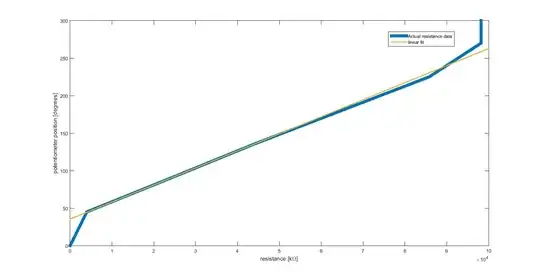

I purchased a rotary potentiometer with a linear taper. I assumed that this meant that from its lowest position to its highest it is linear in its resistance change. However, I've found that this only holds for approximately 180 degrees, after which the resistance is nonlinear. I've attached a figure below:

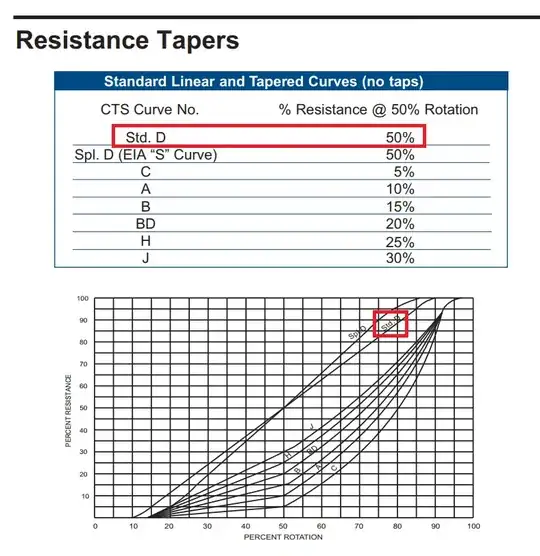

Here's the datasheet. It doesn't contain any resistance data other than to say it is linear (unless I'm totally missing it).

Interestingly enough, this is for a 1st year circuits lab, so it's actually better if this behaviour is typical. I could, for instance, as them to analyze their data and choose the range for which the linear relationship holds. However, if my pot is broken then I'm obviously not going to do that.

So, is it my potentiometer that's the problem, or is this a normal thing?