I have an outdoor electronics project which is running 5V DC through 12 AWG wire to power strands of LEDs through 24 AWG wires. The strands are powered in parallel like so:

5V/GND --------------------------------------- ...

| | | | | |

| | | | | |

| | | | | | ...

| | | | | |

LED1 LED2 LED3 LED4 LED5 LED6

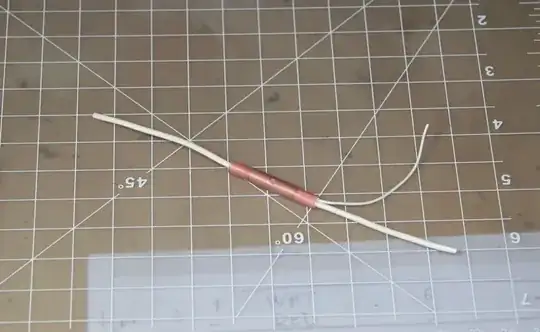

My first try to get them connected was to use weather proof wire nuts to connect the wires together (so each nut has two 12AWG wires and one 24AWG wire). However, I don't think this is a good solution as these wires will need to be able to move with environmental events (wind, rain, etc.) and it seems like the gross mismatch in the wire gauges will cause the LED power and ground wires to be pulled loose.

I can't make the gauge of the power supply wires smaller since they run over about 50 feet and I don't want to suffer a large voltage drop, and I can't directly make the LED power wires thicker.

So, are there other any good connectors I can use, taking into account the large difference in wire gauges I'm working with?