How does one interpret the numbers when reading data about tensile strength, yield strength, and the likes?

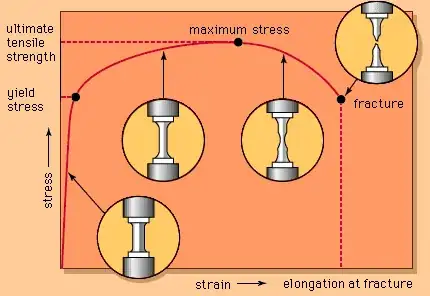

Say for example reinforcing bars. Grade 40 Rebars are rated at 70,000 PSI for its ultimate tensile strength and 40,000 PSI for its yield strength. I know a material's tensile strength is the point in the stress-strain curve at which the material will ultimately fail while the yield strength is the point on the curve at which the material will permanently deform (correct me if I'm wrong).

What I don't understand though is where this stress (pressure?) is supposed to be applied on the object for it to break. What does the "per square inch" (or whatever unit area) point to, the cross section? How should I interpret this data if I plan on hanging some load directly on the center of a rebar whose ends are securely mounted by the ends? What if the load is evenly distributed throughout the bar? What if I use a pipe whose center is hollow?

I need to understand this in a practical sense and not just numerically since I'm planning on building some equipment where structural integrity is a must. I'm pretty sure interpreting this should be fairly simple, but I can't seem to get a grasp on the 'real' and 'practical' side of this, regardless on how much I use Google and Wiki for this.