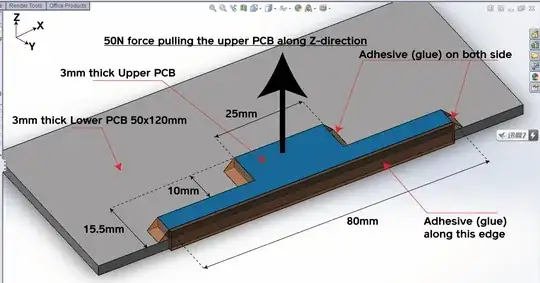

I have two PCBs (Printed Circuit Boards), and they are glued by adhesives, as shown in the pictures. The location of the adhesives is indicated in the picture (please notice that no adhesive is applied between the PCBs).

A $50 \ \text{N}$ force is applied on the upper PCB ($z$-direction). I use adhesive to prevent the PCB from being separated.

Here are the dimensions of the adhesives:

All the wedge-shaped adhesives have a height of $3 \ \text{mm}$ ($z$-direction) (the same as the PCBs), and the width is $1 \ \text{mm}$ ($x$-direction).

The long $80 \ \text{mm}$ adhesive is $1 \ \text{mm}$ thick ($y$-direction) and the height is $6 \ \text{mm}$ ($z$-direction).

I read from the adhesive specification sheet that the adhesive has the following properties:

$$\mathrm{tensile\: strength}: 22 \ \text{N/mm}^{2}$$

$$\mathrm{shear\: strength}: 18 \ \text{N/mm}^{2}.$$

How can I judge whether the adhesive is strong enough? What kind of formula should I use?

I attempted to solve the problem like this:

Step 1:

$$ \text{Total area of glue contact on the blue board} = 2 \, (3(10) + 3(5.5)) + 80 \, (3) = 333 \ \text{mm}^{2}$$

$$\text{Force resisting detachment of the blue board (shear force only in this situation)} = 333 \, (18) = 5994 \ \text{N}.$$

Step 2:

$$\text{Total area of the 4 glue contacts on the grey (ground) board} = 2 \, (1(10) + 1(5.5)) = 31 \ \text{mm}^{2}$$

$$\text{Area of the glue contact at the edge of the grey board} = 80 \, (3)= 240 \ \text{mm}^{2}.$$

So: $$\text{Total force resisting the glue from being pulled out from the grey board (tensile + shear force in this situation)} = 31 \, (22) + 240 \, (18) = 5002 \ \text{N}.$$

Therefore, in $5002 \ \text{N}$, is required to pull the blue out?