I am familiar with the known formula to find Reynold's number in a circular pipe for newtonian fluids:

$$\text{Re} = \frac{\rho \bar{v}D}{\mu}$$

where $\rho$ is the density, $\bar{v}$ is the average velocity, and $\mu$ is the viscosity of the newtonian fluid; and $D$ is the inner diameter of the pipe.

At first, I presumed finding the $\text{Re}$ value for a non-Newtonian fluid is pretty straightforward: replace $\mu$ with whatever is equivalent for a non-newtonian fluid. I know that newtonian fluids hold the property that the viscous shear stress on any infinitesimal surface $dS$ is proportional to the velocity gradient along the normal of $dS$:

$$\tau \propto \frac{dv}{dz}$$

where $\tau$ is the viscous shear stress. Of course, the proportionality constant here is $\mu$.

For non-newtonian fluids, the shear stress is not proportional to velocity gradient, but still remains a function of it:

$$\tau = f\left(\frac{dv}{dz}\right)$$

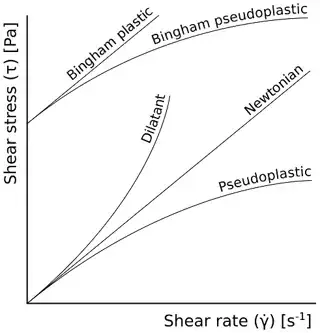

Various types of non-Newtonian fluids have been experimentally discovered, such as pseudoplastics and dilatants, with their shear-stress and shear rate (velocity gradient) relations:

I thought we must use the "viscosity-equivalent" for non-Newtonian fluids:

$$\mu_{\text{equiv}}=\frac{\tau}{\gamma}$$

where

$$\gamma = \frac{dv}{dz}$$

This becomes:

$$\mu_{\text{equiv}}=\frac{f(\gamma)}{\gamma}$$

This "viscosity equivalent" becomes a function of shear rate. This is where I hit a roadblock:

In a circular pipe, the shear-rate at different distances from center are different, and thus, the "viscosity equivalent" is different at every point in the pipe. What should I substitute $\mu$ with in the newtonian formula to get my result for any non-newtonian fluid?

If my entire premise was wrong, I would like to know how I may obtain the Reynold's number for a non-Newtonian fluid.