The design of a power station cooling tower is such as to meet a number of requirements:

- Heat loss rate

- Water recycling

- Structural strength

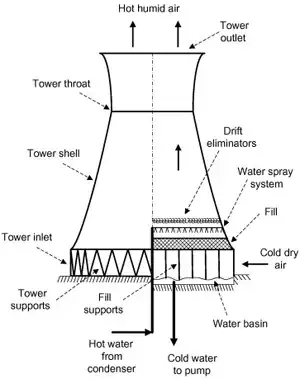

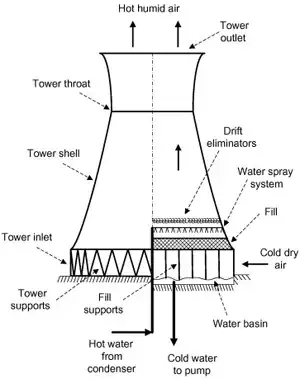

Basic operational model

(See schematic below) Hot water flows to the cooling tower in pipes to sprays on the inside of the cooling tower, at elevated positions. Water drops from the sprays towards capture ponds at the bottom.

Cool air is used to cool the falling water: the cool air enters through the bottom gaps and flows upwards through the inside of the cooling tower. As the air rises, it meets the falling water droplets, cooling them and gaining heat. The warmer air rises through the tower towards the narrowest point, increasing in velocity as it does so. After the air has passed the narrow point, mixing with atmospheric air begins. As it mixes with the air it is cooled more rapidly , keeping the top of the cooling tower at a lower pressure than the bottom, thus maintaining air flow.

Design and Compromises

Heat loss rate

Reason for general shape: hollow structure is required through which hot air from the bottom, to a cooler top, which is at a lower pressure. More air flowing through the tower means better cooling, so a tower allowing more air to pass through is best (wider tower, more gaps at bottom). The air flow is driven by the difference between, the pressure just after contact with the hot water temperature, and the pressure of the air just outside the top of the cooling tower. This pressure difference is a function of the gradient between the air temperature as it interacts with the hot water on its way up, and the temperature of the air outside the top of the cooling tower.

Water recycling

The hot water should ideally all fall to the collection ponds after being cooled by the air.

However, some of this water evaporates, following the air column upwards to the atmosphere. It is therefore necessary to limit the speed of the air flowing through the inside of the tower to reduce water loss to evaporation. This can be done by limiting the temperature gradient between the top and bottom of the tower, i.e. limit tower height (hot air rises more quickly through a relatively cooler stream of air), and/or limit flow rate of hot water through the sprays of a single cooling tower (build more cooling towers).

Structural strength

For functional reasons, the cooling tower could well be a series of straight line cones, but the hyperbolic shape of the sides of the cooling tower provide very good strength as compared to other shapes (Ref).

Also, most cooling towers I've seen have the hyperboloid shape extend

past the narrowest point by what appears to be roughly the same

amount. Is there a reason for this?

If one can get away with lowering the neck of the hyperbola, but the base remains wider than the top, for a fixed minimum diameter, this clearly means less average diameter, and thus less building material costs.

Schematic of a cooling tower (Ref)