"Worn" would be detected by too much ring gap. Mind you, there are two things which can increase ring gap. The first is, as you suspected, the ring itself wearing. As it gets older, it will wear down on the face which rides against the cylinder bore and this creates more ring gap. There is another aspect of this which you may not realize. That is if the ring itself is wearing, the ring will be weaker against the bore. This, too, can allow combustion gasses to get past as there isn't as much tension on the ring where it meets the cylinder wall.

The second thing is the cylinder may be broader at the top than at the bottom of the bore. As the pistons go up and down in the cylinder, the rings tend to wear the top part of the cylinder more than the bottom. This is most notable when there's a thing called a ring ridge (extreme cases). This happened a lot more in older engines with weaker materials in the cylinder bores than what you see today. You'd need a special tool (ridge reamer) to take the ridge off to get the piston out of the bore. Anyway, as it wears, it'll have a broader bore at the top, which if you measure the ring in this spot, it will show to have more end gap because the ring is allowed to be further sprung than it would be in normal bores. If your bore is worn, you may be seeing this in your measurement.

The edges of the rings won't become rounded over time, unless there is a physical problem with the piston ring lands. This would only happen if the pistons were so worn the ring could flex, but I don't think I've ever seen this happen. Usually (and I'm saying almost always here) the ring will wear perpendicular to the bore, meaning the outcome of the ring edge riding on the bore will be squared off.

I found this video which goes in depth pretty well about ring gap in forced induction situations (Note: I don't usually watch this guys videos because the cadence of his speech drives me batty ... he has good info some times).

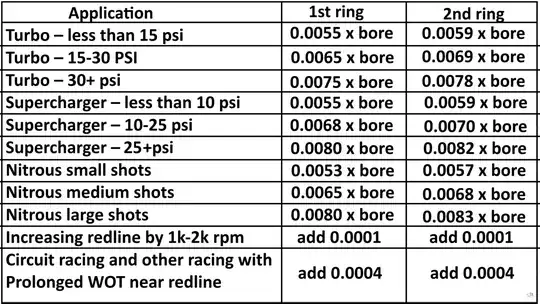

On the video he has this chart:

Two things about this chart. First, the measurements are metric. Second, you'll notice it shows there is a different (larger) ring gap for the 2nd ring. He talks about why in the video, but basically his reasoning is there is always some blow by of combustion gasses past the first ring. If the 2nd ring end gap is smaller or the same size as the 1st ring, it can trap the combustion gasses and pressure between the two rings and cause issues.

To figure out how much gap you need, you should multiply the number in accordance with your boost against the size of the bore. Pretty simple procedure. In the video he does state the values given err on the side of caution and are a bit on the large side. He does give this note in the video:

Note: This table is only a guide. It also errs on the safe side and goes for a gap on the large side. There are other factors to consider too, such as the type of intercooling, water/meth injection presence, etc. In general, if you can reliably maximize the cooling of the intake charge you can decrease the gap factor by 0.0001-0.0002

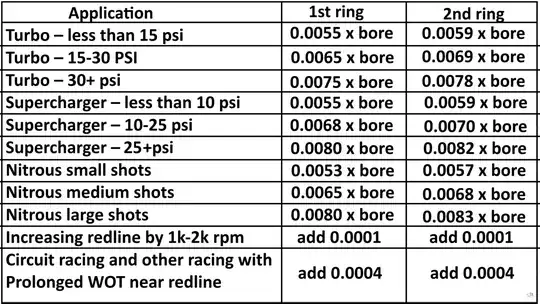

EDIT: Another video popped up in my YT feed, so thought I'd add it here. Their big takeaway was, "You can not go wrong with it too big. You'll get in trouble if it's too small." Here's the video from Total Seal Piston Rings. If anyone knows this stuff, it's these guys. Also, they offered another chart which makes it easier for those with Imperial measurements: