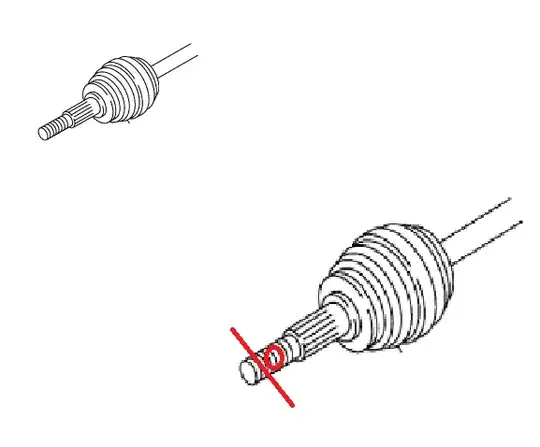

Just went ahead to change my transverse link/control arm, the drive shaft was stuck assuming from rust and I couldn't get it free, hammered it with the nut on and nothing, then with the nut off and it came loose. Such a stupid mistake as I damaged the threads on the driveshaft, as well as the nut. Now the car is undrivable of course.

The threads are damaged only on the first few about 7mm of the driveshaft start point, far away from the cotter pin hole (thankfully).

The nut is also toast though. From the damaged start threads whereby just putting a new nut on will damage it as well and probably further up the shaft itself.

I have removed the driveshaft off several times prior and never had the nut itself loose/damaged cotter pin.

I am thinking of grinding the broken threads down up until the good section and thereby just put a new nut on? However I am just wondering how can I make it so that the new nut doesn't get damaged/stripped as well, does there need to be a sort of cut "entry" groove?

I don't fancy changing the whole driveshaft end.