jxramos, did you watch that video from the beginning? In the first minute, the presenter warns viewers to remove refrigerant before any repairs, suggesting a local repair shop. Legally, refrigerant must be removed into reclamation canisters (15/30 lb capacity canisters labeled for reclamation) by licensed repair shops abiding by EPA regulations since they're likely to perform many repairs to vehicle ac systems. However, in reality, leaks release refrigerant that no one can control when it occurs. Again, refrigerant must be removed before repairs begin as standby pressures (ac off, ambient temperatures) vary more or less direct proportion to outside temps. 75F/75 psi, 95F/95psi - sealed system pressures. When running, high side pressures can easily exceed 200 psi - not diy friendly when attempting to monitor pressures without familiarity about hazardous conditions around working ac systems. The two service valves are for anyone familiar with using gauges and the eventual repairs needed when ac fails. Disconnecting any ac fitting without understanding standby pressures can result in an immediate high pressure (approximately 75 psi) discharge of refrigerant and oil to blind anyone not wearing eye protection. It's said that FAA regulations related to flying are paid by the blood of accidents and crashes and the investigations to uncover the causes and make recommendations to prevent repeating mistakes. Vehicle ac repairs are no different with safety procedures already well known to allow anyone a safe procedure when working on ac problems.

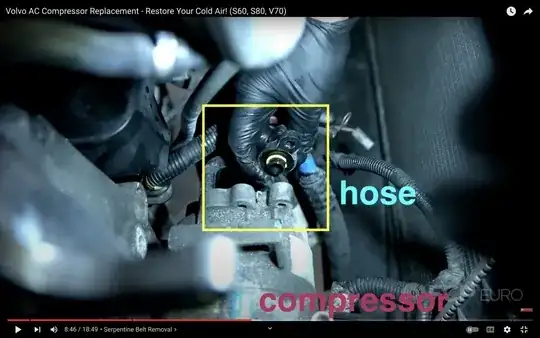

Because sealed ac systems will leak, eventually, knowing what refrigerant remains determines if its safe to open fittings with an empty system or removing the bulk of it into a reclamation canister using gauges and (electric) vacuum pump. Repair shops not using reclamation canisters can be fined thousands of dollars for allowing release of refrigerant into the atmosphere. Diyers discovering their empty systems already released refrigerant are generally not subject to being cited for inadvertent leaks. Once a system is depressurized, fittings can be safely disconnected. Since oil circulates freely throughout a system, you're likely to find oil (and dye if installed at factory assembly) on your hands. Repairs must be kept clean to prevent debris from getting into a system that can accelerate compressor wear. R134a O-rings are prelubed with r12 mineral oil - it doesn't absord moisture.

Once you become familiar with diagnosing and troubleshooting your system, the reason for replacing seals may not be as simple as it appears. R134a systems use pag oil that readily absorbs moisture. A leak will release refrigerant, dye and oil, attracting moisture to the leak area. Moisture will begin to corrode bare, untreated aluminum parts in every ac system. This can erode the precise fitting surfaces in each fitting that mates to allow the O-ring a leak free seal. Corrosion allows uneven protrusions preventing proper sealing against pressures. Fitting faces should be at least free of any corrosion preventing re-sealing with new O-rings. Guess how I know? Overtightening of aluminum fittings or replacing seals will not correct for corrosion. Remember, fittings on the high side (discharge side of compressor, hose, condenser coil, receiver/drier, hose to input side of the thermal expansion valve, will be under pressure between 125-250 psi. While ac systems are not rocket science, familiarity is needed to work on them. I like the analogy; if you do not understand super or turbo chargers, then it's not a diy friendly repair if it breaks down. The same for vehicle ac systems.