Custom 4-cylinder boxer, based on a Volkswagen/Porshe of some kind (not entirely sure what), with the starter from an '85 Nissan Sentra or thereabouts. (generic part number 16816)

Video of two attempts with fuel and spark disabled, and oscilloscope captures of the solenoid and motor terminals:

https://www.youtube.com/watch?v=xhyJddXH4es

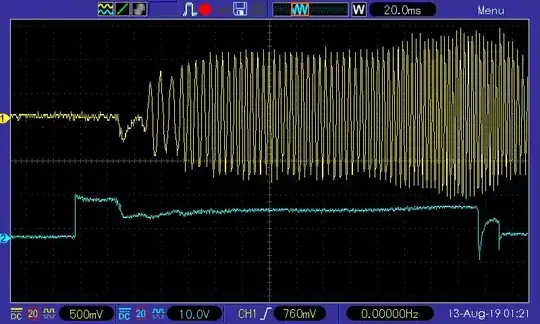

The video shows a single engagement for each attempt, and then the gear drops back out and grinds, but it has also "bounced" for several successful engagements before finally grinding as shown in the video. The 'scope shows some wiggle, but no dropouts.

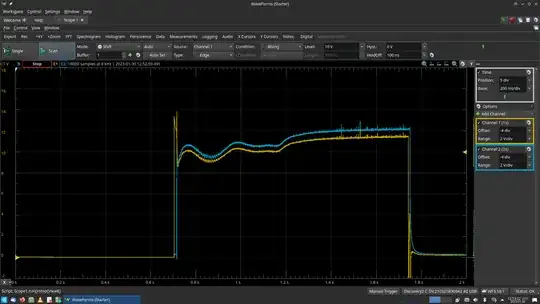

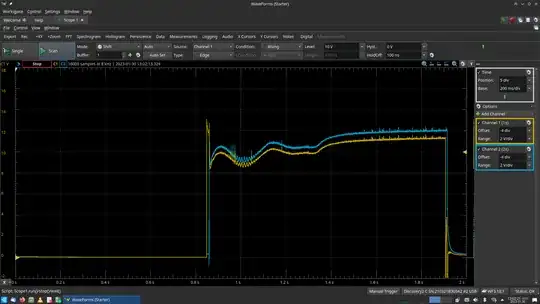

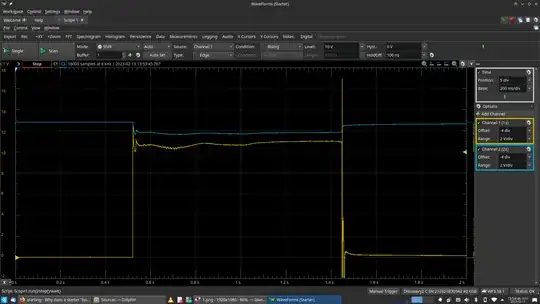

Same two screenshots from the 'scope:

Yellow is the solenoid tab.

Blue is the motor terminal, after the contacts.

The best I can come up with is that the compression release (what would have been a power stroke) is enough to turn the engine faster than the starter does, and so the helix pushes the gear back down as if the engine were running. But because it's not running, it needs to re-engage, which leads to the "bounce". Is that reasonable?

It's been shimmed in various ways, asymmetrically as an attempt to either fine-tune the mesh, or use the angle to try and drive the gear out, and the mounting holes have been wallowed out to allow direct adjustment before tightening down again. During all that, it's been obviously too close (never popping out, just grinding) and too far (popping out and still grinding), and in between it seems to work...if it would just stay engaged, which it never does.

Going off of the "engine-too-fast pushing the helix down" theory, I found that if I disable the motor and only power the solenoid, I can easily push the gear back down with my finger. Does that indicate a problem?

A professional starter repair shop saw that video, kept it for a week, and ended up saying it was fine. So they didn't do anything, and it still has the same problem.

Any ideas?

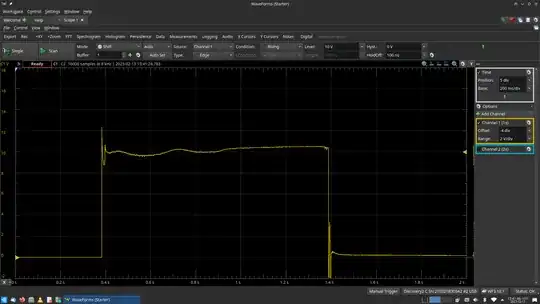

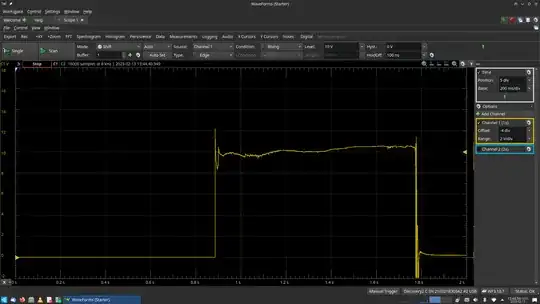

More testing, same result:

A small auxiliary battery that only runs the solenoid, does this, measured at the solenoid tab:

That battery plus a booster pack:

Without the booster pack again, but used the second channel (blue) to watch the battery itself:

Looks like these test leads are too small, and the auxiliary battery could be a bit bigger as well. But I don't have bigger clip leads at the moment.

The regular wiring is about that size too, so maybe that's part of the problem?

Also noticed that the aux battery still has the same wiggle on the solenoid tab. It's less pronounced, but still there. I thought it inherited that entirely from the motor, but there's no connection to that anymore, and it's still there.

Got some 4AWG jumper cables to replace the 22AWG clip leads...plus about 2 feet of 10AWG to snake into where the solenoid tab is and have the right connector on it. Clipped the jumper cable onto the starter mounting bracket, and the other end of the 10AWG, and then about 5 feet from there to a standard car battery on the ground.

No change. Still saw about 10 volts between the solenoid tab and the mounting bracket, and 11 volts across the freshly charged full-size lead-acid car battery. (a smart charger had just clicked off)

An ohmmeter across the solenoid measures a dead-short circuit - 0.0 ohms - which is slightly odd because holding the same leads together reads about 0.2 ohms. Bad solenoid?