From your comment 2:

Any damage I should be checking for that could've resulted from the wrong installation?

Yes, this is a serious safety concern.

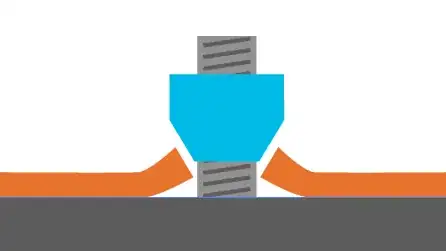

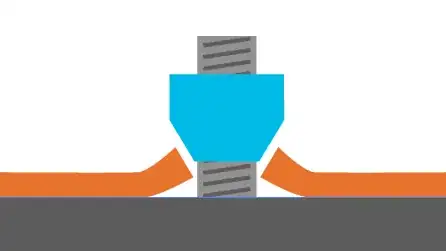

Here is how lugs are supposed to work.

(loosened, for clarity). Gray is the hub and bolt. Orange is the wheel rim. Blue is the nut. Notice how the rim is somewhat oversize on the bolt - the bolt is not a locating pin for the rim (at least, not without the nut, it isn't) and there are several millimeters of lateral (on the car, up/down) free play without the nut being involved.

The inside of the holes on the wheel are beveled. They match the bevel on the lug nut when they are installed correctly. These bevels hold the wheel at center to keep it from drifting around when rotating.

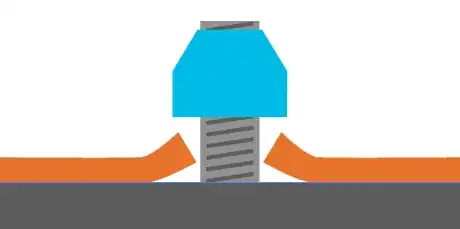

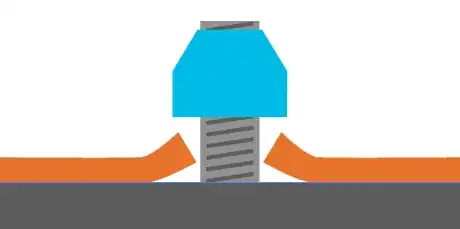

Now let's try it with lugs upside down.

By putting the flats of the lug nuts into the bevel of the wheel, look at the surface contact area between nut and rim! It got a lot smaller! So yeah, most likely, if you torqued to spec, that would make the steel deform plastically on the rim somewhat - it would be difficult to avoid. Also, the "locating pin" function of the nuts is now inoperative. So, by rolling the wheels in this state and letting it shift around on the nut flats, it could do more damage.

So yes. The new rust pattern could well be either from distorting the metal due to the high force on small contact area, or due to the wheel "working" round and round.

And yes. That would be reflected in a new rust pattern.

I would look closely at the shape of the wheel where it meets the nuts. If the bevel on the rim seems intact, you can probably put the nuts on properly and forget about it. Otherwise I'd be shopping around used wheel shops and see if you can get an OEM match off another car. This is not too expensive on OEM steel wheels.

The bevel on the lug nuts (blue) is unharmed. Even if their backside is a little chewed up, that's not a critical surface.

You didn't ask, but, aesthetics...

Correcting the telltale rust pattern would be shooting the helpful messenger. However, since some expect an aesthetics answer... If I had spare wheel/tires and a buddy with a sandblast cabinet, I'd blast these down to near white metal. Otherwise I'd go to town with a real drill (not a drill-driver; too slow) and a quality wire-wheel cup or disc (you don't want dollar-store junk for this). Wear safety glasses. Then (before they re-rust) I'd immediately mask the rubber and prime with Rustoleum 7769 from a rattle can. Taking care to do multiple light coats; no runs. Then hit it with gloss or flat Rustoleum topcoat from a rattle can again multiple light coats. I'd do them away from the car, one at a time if necessary. Often, I can't media-blast and the best surface preparation I can manage is SSPC-SP-3 (wire wheel). I've tried a lot of industrial trade-only products, and nothing works as well as plain old hardware store Rustoleum 7769 under a quality topcoat.