Throttle body and intake manifold are both made of plastic in my car. Every few years, I remove throttle body to clean Idle Air Control Valve passageway because it is inaccessible without removing the throttle body.

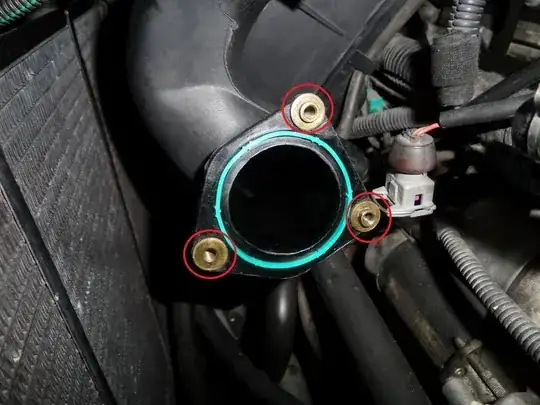

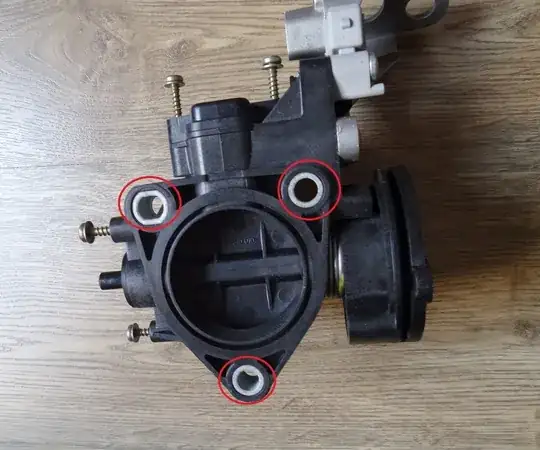

My throttle body is attached to intake manifold through 3 bolts (They are M6 Allen bolts). I know that proper torque values for such bolts is around 10 - 11 nm (7.37 - 8.11 lb-ft).

However, since the parts are made of plastic (which is not strong), I always tighten the bolts with a simple screwdriver only by hand without using any leverage because I'm afraid of breaking or cracking the plastic parts which are quite expensive.

Recently, I made a simple experiment to know how much torque I'm applying to the bolts when I'm tightening them with a screwdriver and the result was somewhere between 4.5 and 5 nm (3.31 - 3.68 lb-ft). Do you think this amount of torque is enough for throttle body gasket to seal against intake manifold? (the green gasket in the picture). Should I tighten them a little bit more?

As can be seen in the following pictures, the thread housing of the bolts are made of metal but I'm still not sure how much torque they can take before any deformation or crack happens.