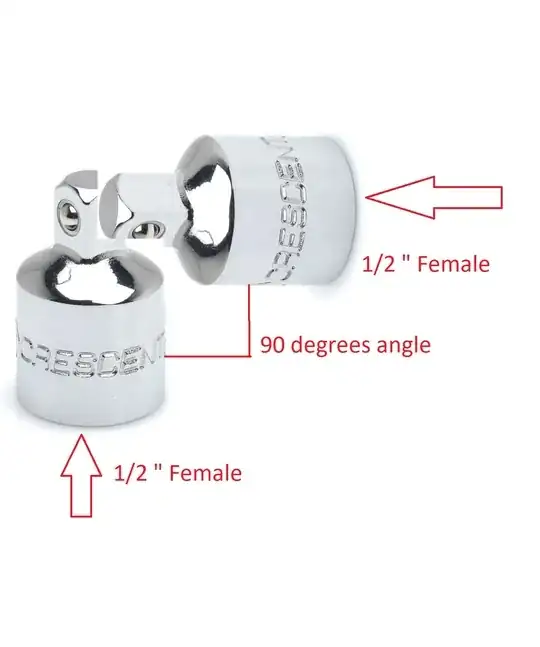

I need to have a special adapter that is formed by connecting two 3/8 " to 1/2 " adapters at 90 degrees angle. I want both ends of the adapter to be females only.

I have two of these:

And I want to attach them together like this without welding:

Is there any official adapter on the market to do it for me? Do I have to make one?

It is hard to find a L-shaped piece of metal and drill square holes on both ends of it.

=============================

@HandyHowie

As promised, I returned with pictures and more info. You asked about what I have done with my Allen key and two sockets.

These are my two 10 mm sockets and a 10 mm Allen key:

I connected the sockets to both ends of the Allen like this:

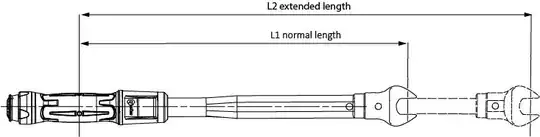

This is my torque wrench and a 1/2 " extension bar:

Now I connect the extension bar to the square drive of my torque wrench to form a long extension:

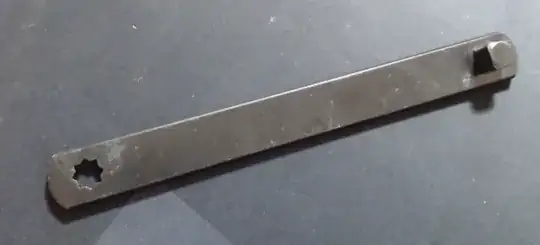

However, the above extension bar was just an example for demonstration purposes. I have another L-shaped extension bar that I want to connect to the torque wrench with the same method.

This is my L-shaped 1/2 " extension bar which I want to attach to my torque wrench:

Why I don't use this Allen Key method? Because the sockets need to be welded to Allen Key and I prefer to use welding as the last resort.

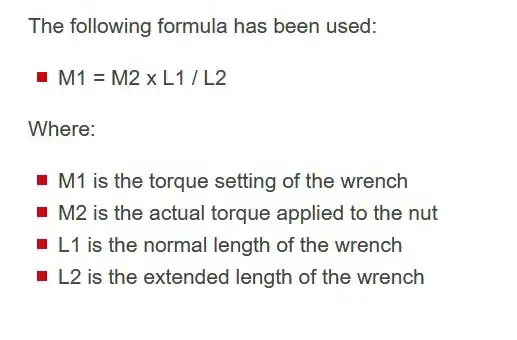

This way I can increase the torque and the following formula (which is offered by torque wrench manufacturers themselves) help me to know how much more torque I will apply to the fastener in each torque setting.

For instance, my torque wrench is 0.36 meter long. Without extension I need to apply 22.66 kg to its handle to produce 80 nm of torque. With my extension (0.42 meter + 0.10 meter the length of Allen Key = 0.52 meter), I need to apply only 9.27 kg to my torque wrench to produce the same 80 nm.

The main benefit of the extension is that it increases the maximum torque capacity of my torque wrench.

My torque wrench supports a range of between 15 and 80 nm. My lug nuts require 90 nm which exceeds my torque wrench capacity. With the extension, I need to set my torque wrench to 37 nm to produce 90 nm!