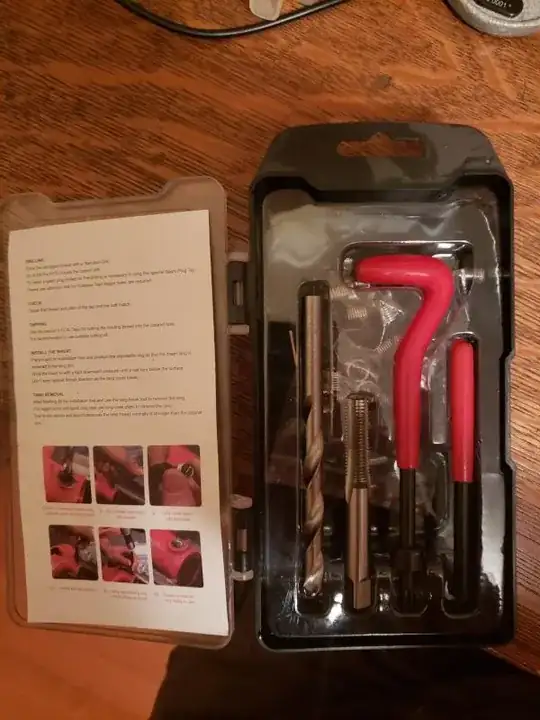

This thread repair kit came with everything but a handle (T-grip) to set the tap into when driving it in. The tap itself is the second one from the left.

The driver side of the tap seems to be 8 mm square:

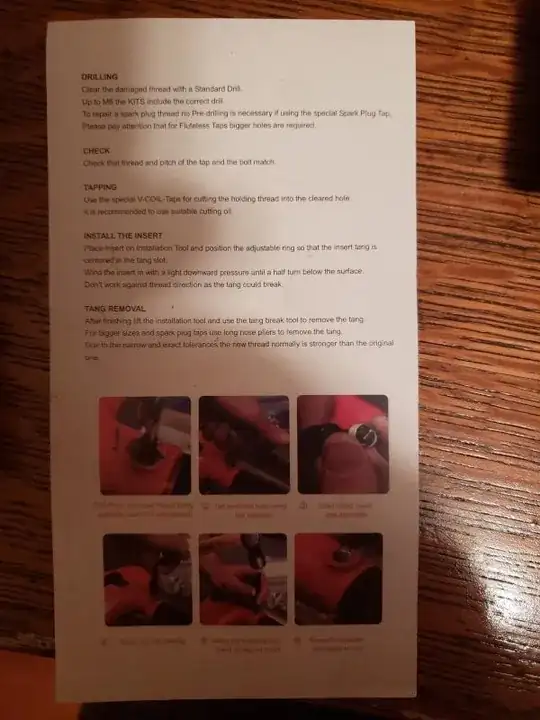

The instructions say nothing about needing a special tool for the tap:

Which tool can I use to drive this tap? Also, the kit didn't come with cutting oil, which I didn't think would have broken their bank to include. Is it really needed? I am cutting threads in an aluminum engine block.