I have an aluminium clamp on a bike where the thread has stripped. The steel bolt is okay, but the clamp has very little movement - I can't get a helicoil or drill through one side of the clamp without drilling out the metal under the shoulders of the bolt.

Fortunately the hole is not blind - I can see up the bottom of it to the leading face of the bolt.

So is it feasible to drill and install the helicoil from the "wrong" side?

I think so, but I've been wrong before. One possibility is braking off the tang will leave a rough "leading" edge that may not engage the bolt smoothly, and would be hard to file.

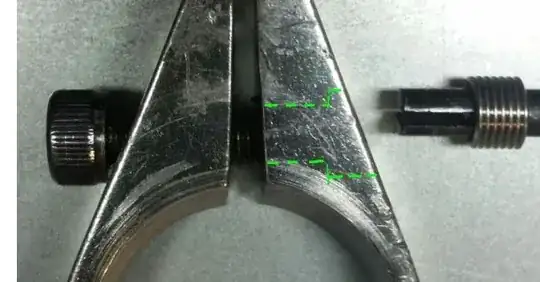

Top view, bolt on left showing normal position, helicoil on right side showing how I want to fit it

Top view, bolt on left showing normal position, helicoil on right side showing how I want to fit it

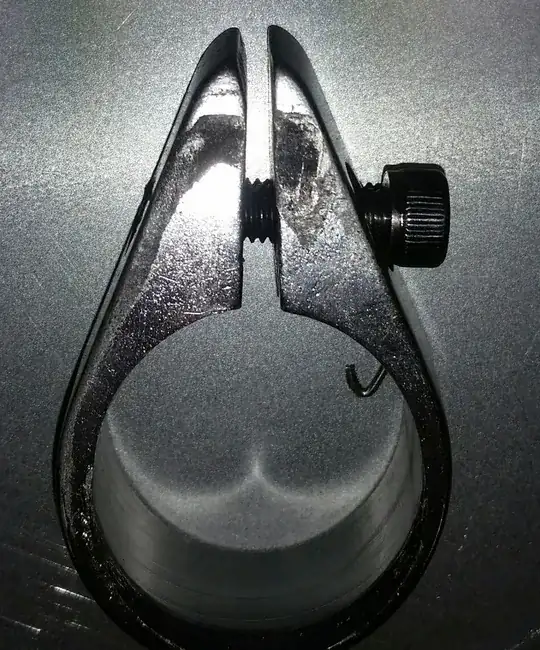

Side view showing edge of clamp inside for bolt's shoulder to rest on. As you can see there's not a lot of metal there, so removing any is bad.

Side view showing edge of clamp inside for bolt's shoulder to rest on. As you can see there's not a lot of metal there, so removing any is bad.

I can't really put a washer on the outside, the top view shows the sides are not parallel. Would have to make a pair of "diagonal" washers, more like a bushing cut diagonally.

Neither the drill nor the tool nor the helicoil itself will fit through the bolt-side hole.

I cannot buy a replacement clamp at any price - they just don't exist. Getting a whole clamp made would be uneconomical.

Here's the place the clamp goes on the bike - commonally available "normal" clamps just won't fit. The bike is 20 years old too so no chance of finding new parts for it. Yes there's a big crack too - thats being hard soldered by a pro next week.

Here's the place the clamp goes on the bike - commonally available "normal" clamps just won't fit. The bike is 20 years old too so no chance of finding new parts for it. Yes there's a big crack too - thats being hard soldered by a pro next week.