This is in addition to my previous question about throttle bodies. I know it may sound a bit subjective, but I think it has a clear technical aspect, and I have done a considerable amount of homework.

To elaborate; I'm looking for a throttle body to replace my SU carburetors. The carburetors, have a bore of 45mm. It's obvious that you don't want a TB (throttle body) that's too small because that would restrict the airflow. You wouldn't want to go too big either, because the response would probably be really weird. If 20% throttle would give you full power already, that would be annoying. I suppose manufacturers choose a TB that is, with a little margin, just big enough to be not restricting at WOT at max rpm.

I was wondering if it would be smart to go for a bigger TB that is not restrictive anymore at WOT at max rpm, when it's only opened for say, 50 degrees. I'd set the pedal travel accordingly; pedal to the metal means throttle opened for 50 degrees from shut. Because the TB is much bigger, but opened only partially, you still have the swirl/turbulence that the throttleplate creates, while also keeping maximum manifold pressure or volumetric efficiency.

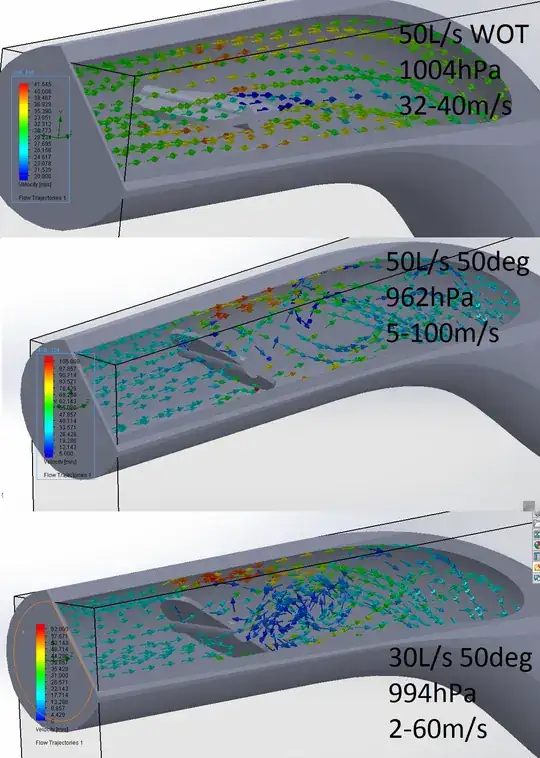

I have flow tested it in SolidWorks and you can clearly see the difference. It's a 2 litre 4 cylinder twin carb/TB. So at 6000rpm you'd get 50l/sec per TB. The ambient pressure is 1013hPa. The colour of the arrows represent the air speed in m/s.

At WOT, there's virtually no swirl, and the MAP barely differs from ambient pressure.

At 50degrees opening, there's much swirl but the MAP drops significantly.

At 50 degrees, but with 5/3rd of the volume airflow(30L/sec), you still get the swirl, while also keeping a MAP that's almost as high as ambient.

The same would be true for 50L/sec but with a bigger TB. So in my case i'd choose a 75mm TB over a 45mm one; 5/3rd bigger than normal. More swirl means better atomization, better atomization means more complete combustion, more efficiency, and more power.

I'm inclined to think there's a reason manufacturers don't do this, but I can't see a downside in this concept. Obviously one would need to make an smooth conical-like adapter to properly fit the TB to the manifold.

What do you guys think?