Your torque wrench is not 100% accurate, so aiming for the limits may end up over or under-torquing it. Best to go for near the middle of the range. A modest torque wrench might be accurate to +/-4% of indicated value over a the stated range.

So why the **** do they specify a range rather than simply give the nominal torque, you might well ask- the range gives you an idea of how close to the nominal that the engineers want you to get it. If they have specified a very narrow range, you may not be able to achieve it with the tools you have.

Of course if you over or under-torque the fastener you risk it coming loose, or breaking or stripping the fastener.

Take particular care to get the torque near right on parts that have relatively high torque for their size such as caliper bracket bolts, and especially on parts that are specifically stated to be one-time use (they are designed to stretch a certain amount when installed and must not be re-used).

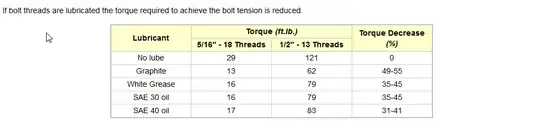

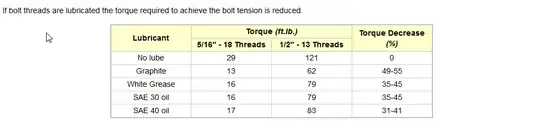

Also pay attention to whether lubrication is applied: