I've got a 2.5 L engine here for which I do not know the performance specs (yet), because it's customized.

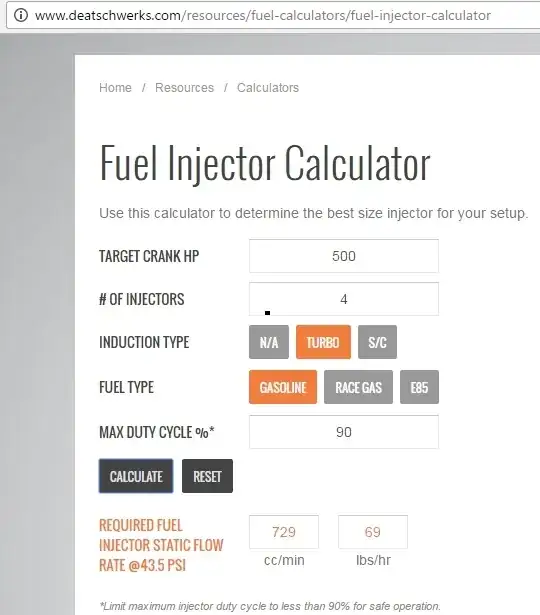

I need to select injectors for this build, but there seems to be only one equation on the interweb to get the injector size, and this takes the engine's power in account, which I don't have.

My idea was to calculate the maximum mass airflow that the engine will displace, and then calculate how much fuel gets mixed with that at the richest AFR I will ever maintain (12.05). Then dividing by max. duty cycle should give me the injector size. I took 100% VE at WOT.

This is the result:

Specific air mass: 1.27 kg/m3

Specific fuel mass: 0.75 kg/L

Volume air flow: 6000rpm * 2.5L * 1/2

= 7500 L/min = 7.5 m3/min

= 0.125 m3/sec (because 4 stroke)

Mass air flow: 0.125 * 1.27 = 0.16 kg/sec

Mass fuel flow: 0.16 / 12.05 = 0.013 kg/sec

Volume fuelflow: 0.013 / 0.75 = 0.018 L/sec = 1062 cc/min

Duty-Cycle 0.8: 1062 / 0.8 = 1328 cc/min

This looks a bit too high to me... VE and AFR could be a bit lower but it'd still be too large.

Is there any other method to determine injector size?

Cheers