A tap/die is not the same thing as a thread chaser - while it can be used that way, you have a higher risk of cutting new threads instead of renewing old threads.

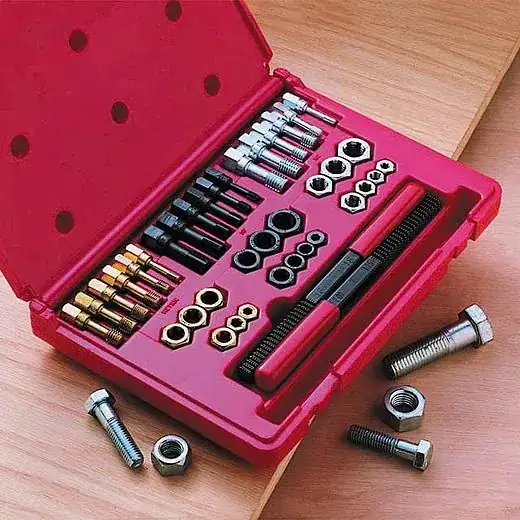

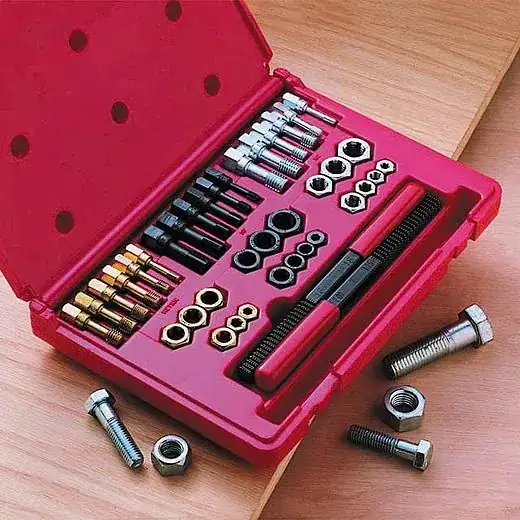

A proper thread chaser will clean up old threads with a much lower risk of cross threading. They can save threads that appear destroyed and are well worth the expense. Here is a Craftsman set that I use with great success (as of a couple years ago, still made in the USA):

EDIT: Confusingly, this set is labeled as a "tap and die set" but you can see in the picture that the threads are much less aggressive than a regular tap or die.

I bet if you use some penetrating oil like PB Blaster and one of these thread restorers, those welded nuts would clean right up.