What's the point of having a firing order? I read that it helps balance out the power so as not to be too much on one side if the crankshaft, but why do we have such a specific order? If that was the case could I have the firing order in a 4 cylinder engine be 1-4-2-3

3 Answers

There are multiple firing orders for some engine configurations, especially in the V8 realm. A Ford smallblock fires 1-5-4-8-6-3-7-2, while the same displacement modern modular Ford V8 fires 1-5-4-8-7-2-6-3.

There's a huge wiki about Firing Order which contains a vast number of workable arrangements, even across the exact same cylinder configuration.

To answer your specific question, firing order is usually decided to minimize potentially destructive vibrations and mechanical forces that would result if the torque pulses on the crankshaft throws were to harmonize. A similar note is that you will always find engines with a number of cylinders that is evenly divisible into 360 degrees of crankshaft rotation. 4,5,6,8,10,12 are all fine. 7,11 and 13 are not. The exact explanation is beyond me, but it has to do with vibrations and orders of harmonics in combination slider-crank mechanisms.

- 12,432

- 2

- 26

- 47

It depends if you are asking from the point of view of an engine designer or someone trying to maintain or troubleshoot an engine.

From the point of view of a mechanic firing order tells you the order in which the cylinders are ready to fire – when each one is on its compression stroke with the valves closed and a charge of fuel. That's important if you're hooking up spark plug wires (or fuel injector lines on a diesel with a separate pump) or trying to diagnose a rough running engine or one that won't start.

From the point of view of an engine designer, I suspect that, some of the considerations are around concerns like you mentioned – managing stresses and vibrations and maybe also trying to do that without surprising the folks who will work on the engine later.

In answer to your question about other orders, I think – in theory at least, that the designer can have any order s/he wants. The mechanic on the other hand has to follow the order that was designed into the engine.

- 14,506

- 8

- 52

- 85

Firing order is constrained by:

- crankshaft geometry

- piston arrangement (inline, V, VR, flat, etc.)

These two factors will combine to determine when top-dead center (TDC) of each cylinder is achieved with respect to crank angle.

Ideally, the firing order is set up to make the ignition occur as regularly as possible.

Inline-four example

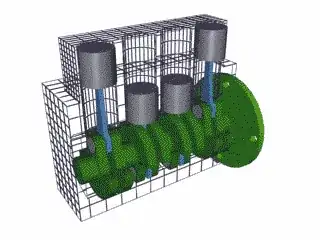

Here is an animation of a regular flat-plane inline-four:

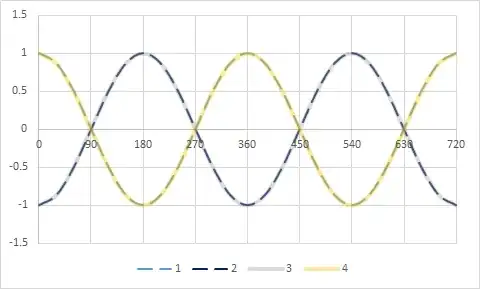

You'll notice that the middle two cylinders (#2 and #3) move in unison, as do #1 and #4. When #2 and #3 are at TDC, #1 and #4 are at BDC, and vice versa. The two pairs are 180° out of phase. Here is what the piston head travel looks like over the course of a 720° crank duration (single four-stroke cycle).

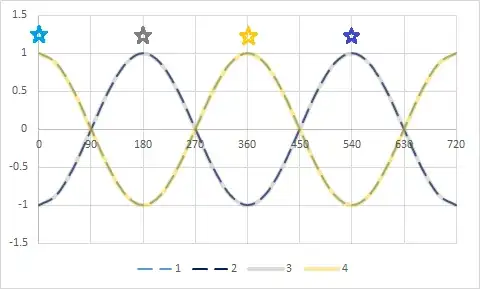

Adding in stars to denote ignition events, it should become obvious why we are limited to what we can use as a firing order. A 1-4-2-3 firing order is infeasible because there is a TDC for #2 and #3 between those of #1 and #4:

Here, there are only two options for firing order:

- 1-3-4-2

- 1-2-4-3

Whenever multiple firing orders are possible, engineers will look to other factors, among which are engine balance, vibrations and harmonics that other answers here have alluded to.

- 39,276

- 50

- 151

- 294