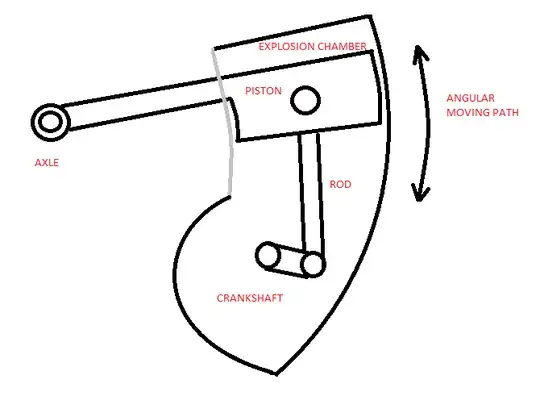

Years ago, I saw a documentary about engine efficiency where people were testing a pivoted, curved-path piston engine. The claim is that the standard piston engine, with straight up-and-down path, causes lots of friction with the walls while the piston travels through the chamber. This friction forces use of expensive rings, and ultimately reduce life span of engine block itself. It also limits linear speed of piston in order to prevent melting and engine failure.

The alternative was to attach the piston to an axle in the top and make it follow an angular path through the chamber. They even displayed a prototype. But I can't find that on the web. If you know about it and can send references, I would greatly appreciate.

If it helps, the engine was being tested for a motorcycle.

EDIT: Added the sketch below to help. While sketching, I found that it requires a sliding window around the rod connecting to the axle, to prevent leaking of gas/liquid. That's probably the biggest weakness. Still I wish to find the team and prototype to confirm that.