There are a few different ways I can think of to do this:

If the vehicle has a manual shift transmission, put the transmission into the highest gear, then set the parking brake. The torque provided through the drivetrain will be more than enough to counteract the torque put on the crank hub bolt. If it's a front wheel drive, have someone stand on the brake pedal, or wedge something onto the brake pedal to hold the front rotors still.

Another way, if it's not a manual shift tranny, is to take the starter out. Then using a long, stout, flat tip screwdriver, find purchase against the starter ring teeth. This obviously requires a friend to hold it in place, but I've found works rather well if you can find purchase. If you cannot find purchase, you may be able to wedge something into the teeth to do the same ... just remember, you have to take it out after you get through torquing the bolt.

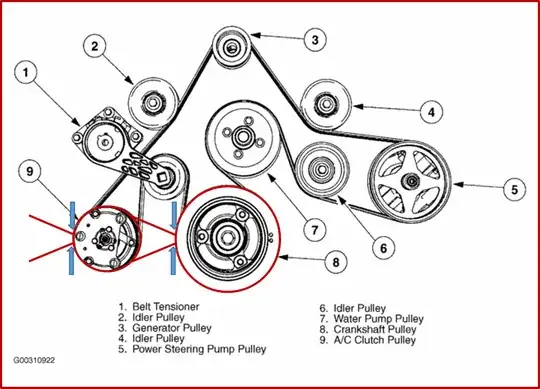

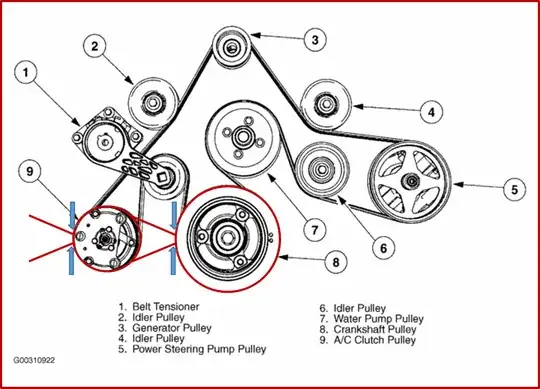

If you have an old serpentine belt, you can wrap it around the crank shaft pulley, grabbing it tight with a pair of Vise-Grips right at the pulley. Then string the other end over another pulley (not the tensioner pulley), grasping that side with another pair of Vise-Grips. As long as the belt isn't completely worn out and you can get a good enough grip with the Vise-Grips, this will hold it for you as well.

EDIT: I came up with this diagram to help you with understanding the above reference:

The blue arrows are the pinch points with the red line being the belt.

If these don't work or you cannot get them to work, maybe they will lead you to another way you can get it to work.