I want to fit a variable geometry turbo to my car. Its vanes are usually controlled an electrical actuator (otherwise sometimes it's on vacuum). What information is used to to inform the state of the turbo vanes, though - throttle position, intake air mass, engine speed, or what? Is there a canonical formula I can use to build a circuit that gives the correct response for given conditions? No problem fitting trimming potentiometers to tune it on the fly, but I need to know what information is suited, so that I can get whatever sensors are called for in play.

2 Answers

Dodge installed VNT Turbochargers on cars in 89 and 90. The most well known of which is the 1989 Shelby CSX-VNT. The vanes were controlled by a dual port vacuum actuator. There was nothing electronic on the turbo itself, but there were vacuum solenoids (for boost control) on the lines going to the actuator.

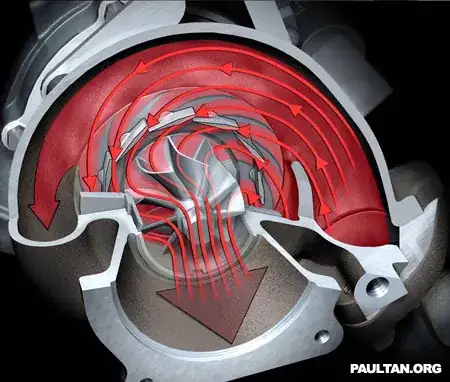

The VNT Turbo has movable vanes on the exhaust turbine. When they are in the 'closed' position, they are more restrictive. This causes the turbo to spool much faster. When they are open, they create less backpressure. This means the turbo handles higher boost better.

Overall, the position of the vanes is dependent upon how much boost the turbo is pushing. The more boost is being generated, the more exhaust gas is flowing, the less restrictive the exhaust side needs to be. This means the vanes open more and more as boost gets higher. When you get near your maximum boost, the vanes start to close to stop the turbo pushing more boost.

The 2 port canister works by having one side open the vanes for less restriction, then the second side close the vanes for maximum boost. The side to open the vanes is connected to the manifold, the side to close the vanes is connected to a boost controller. The spring inside will close the vanes when the pressure is equal on both sides.

Unfortunately, when dodge installed these turbos, they used a turbo that was too small. It would spool super quick (almost no turbo lag), but suffered on the top end. Normally, a VNT turbo is larger than a standard turbo, as the variable vanes help it to spool faster.

http://thedodgegarage.com/turbo_vnt_pictures.html - pictures of the VNT Turbo http://thedodgegarage.com/turbo_vnt.html - Technical information

- 8,458

- 1

- 22

- 31

Disclaimer: I've never done this practically. This answer is based on my somewhat limited exposure to turbomachinery theory in automotive applications.

It's all about the flow

Unlike fixed-geometry turbos, in which the vanes provide optimal efficiency for a single flow, vane angles are adjusted in variable-geometry turbos to enhance efficiency across a broad flow range.

Cue the obligatory images and web article:

What factors can be used to control vane angle?

I expect engine load is going to be key here. Although I have no references to back up this statement, it makes sense since that will directly impact how much exhaust flows over the turbine blades.

To this effect, you may find the following relationships as useful inputs:

- Mass air flow - ↑ flow = ↑ angle

- Throttle position - ↑ throttle position change rate = ↑ angle

Note that relationships are not expected to be linear!

So what will the function mapping look like?

This will heavily depend on your turbo and engine.

If this was my project, I'd follow an experimental procedure similar to this:

- For a given engine speed and throttle position, command several vane angles

- For each angle

- record the mass air flow and boost level

This should give you a very good baseline for steady-state running, since the data can be used to perform a regression that maps mass air flow and throttle position to the vane angle that provides the targeted boost level.

Essentially:

Vane Angle = f( Mass air flow, throttle position, target boost )

As for transients, where rate of change of throttle will feature more prominently, I imagine this will be much more difficult to gather field data for. Maybe someone else can chime in.

In any case, this is an awesome undertaking. I wish you the best in this endeavour.

- 39,276

- 50

- 151

- 294