I'm toying with turbojet engine ideas, and over the course of my research it occurred to me that the combustion chamber could be more power-efficient and space-efficient if it was aligned in the desired direction of airflow.

That said, if the combustion chamber is 1-2 feet long, and both the intake and exhaust turbo manifolds need to connect directly to opposite ends of the combustion chamber, then the intake and exhaust portions of the turbo would need to be separated from each other and the shaft extended to allow room for the combustion chamber.

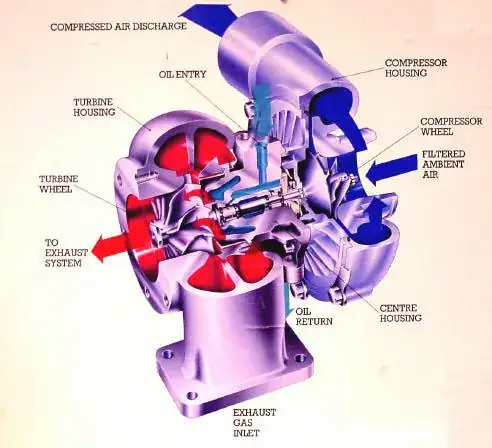

Basically something like the picture below, but with the combustion chamber rotated 90 degrees counter-clockwise-ish to eliminate the long intake tube.

If the shaft were extended, and the compressor further distanced from the turbine, how would this affect the central bits of the turbocharger, and the oil circulation?

(Source for the photo, and here's what it looks like when operating.)