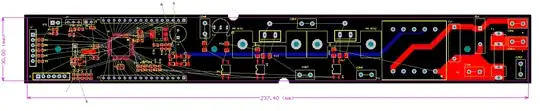

I was wondering if someone can give me advice in routing this PCB.

The PCB contains several triacs driving AC loads and digital end which contains a micro and several digital I/Os. So far, I have decided on the following:

- Use 18 AWG wire to connect the LIVE via the spade terminals.

- Use 5oz copper on the top layer to reduce the track width for the high current tracks for triac output to AC load spade terminal.

- Solder Y caps underneath the board with insulation and hot melt glue.

- Use 4 layers

- First layer contains AC tracks on the mains side and DC signal tracks on the digital side.

- Second layer contains ground layer on the digital side with some signals.

- Third layer contains digital VCC layer on the digital side with some signals.

- Fourth layer contains signals on digital and secondary voltage from the transformer.

I have few constraints in the design like the placements of the headers and AC spade terminals cannot be modified plus the board size cannot be changed. I have placed the heatsink/triacs and spade terminals so I can route the signal tracks to the optocouplers and secondary output of the transformer via the middle of the PCB. I am trying to ensure there is a least 2.5mm separation for the AC tracks.

Do anyone see any issues or problems with this layout or have any suggestions?

Regards Paul