Part number: INA228 from Texas Instruments

MCU: msp430fr2433

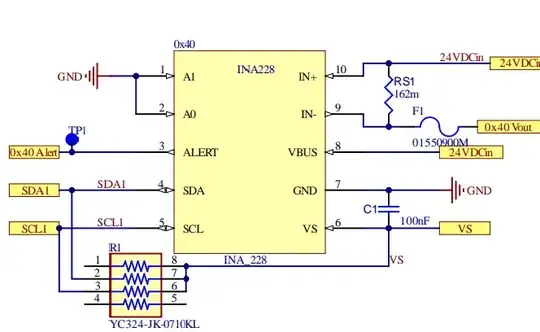

I initially brought a current sensor from Adafruit that used an INA228 chip. After some challenges, I managed to get the I2C communication going and was able to read data from the registers. I cleaned up my code and made a custom board that has 16 of these sensors.

I only soldered one of the INA 228 sensors on my custom board and am trying to see if I can read the registers using the same code.

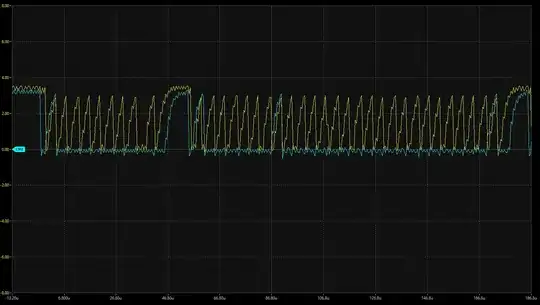

For some reason, my code works on the Adafruit sensor but not on my custom board. Not sure why. I scoped the I2C lines using a logic analyzer. I have attached the captures to this message and also listed the data being transmitted below. Can anybody please explain what I missed on my custom board here?

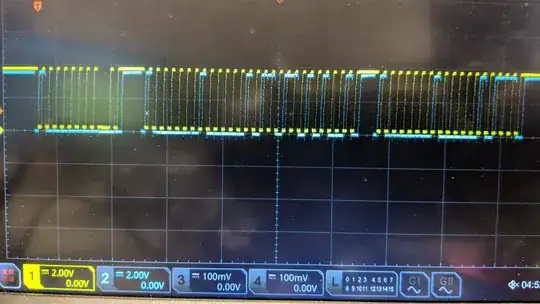

Working data stream: Start -> 0x40 Write (slave address) -> ACK -> 0x06 (temp register) -> Stop || Start -> 0x40 Read -> ACK -> 0x0B -> ACK -> 0xC8 -> NAK -> Stop

Here clearly the data from the register is 0x0b, 0xC8. This translates roughly to 23.56°C. This works. No issues (I think).

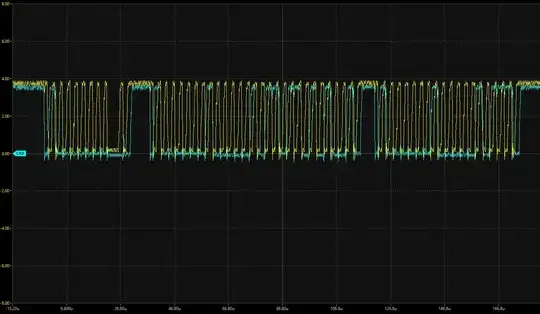

Not-working data stream: Start -> 0x40 Write -> ACK -> Stop || Start -> 0x40 Read -> ACK -> 0x00 -> ACK -> 0x00 -> NACK -> Stop

|| represents a small pause.

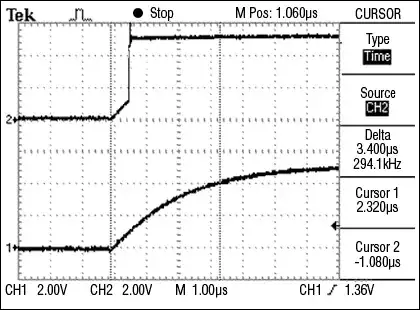

Why is the master not writing 0x06 (register to read) in the custom board case when I am using the same code? Why is the SDA line always low? Is this a hardware or firmware issue?

Not-working logic analyzer capture:

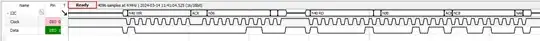

Working logic analyzer capture:

Adafruit sensor: Adafruit sensor

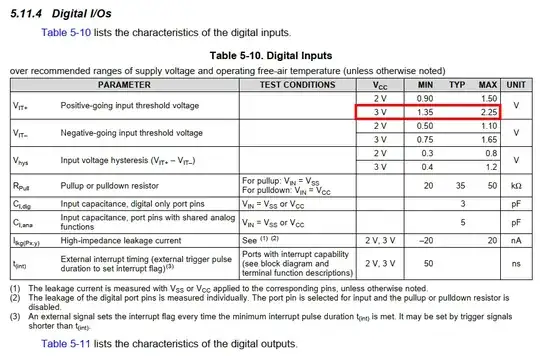

Note: The working board had 4.7 kΩ pull-up resistors. I tried 4.7 kΩ, 24 kΩ, and 2.4 kΩ pull-up resistors, but none of them worked so far. I'm not sure if it's even a pull-up resistor thing.