The robot I'm working on has some some components rate either 360 V or 370 V max (no explicit never exceed values), with nominal voltages of 320 V.

The robot is powered through a very long cable (with not enough copper section to my taste, but there is no alternative for now), so we need to supply the robot with voltages a bit higher than nominal the higher the better (so we still get acceptable voltages at high loads).

Going close to the limits, I would like to add solid over-voltage protection at the robot end of the cable.

Ideally, I would like:

- To clamp short over-voltage spikes. After the clamp, the voltage should never exceed 359 V. The maximal working voltage should be as high as possible.

- For prolonged (or repeated) over-voltage, somehow cut off power (blow a fuse, open a relay or a MOSFET, ...).

There is no precise requirements what duration qualifies as transient, and when it starts being a prolonged over-voltage, the important thing is that the voltage never exceeds 359 V.

The current can be up to 35 A.

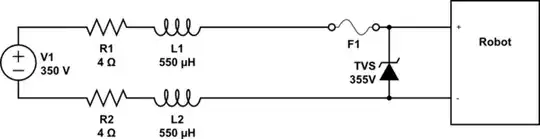

A simple solution would be a fuse followed by a TVS diode:

simulate this circuit – Schematic created using CircuitLab

(R1, R2, L1, L2 represent typical cable resistance/inductance, but can vary by a factor 2 depending on the cable length used)

However, as far as I know, TSV diodes are very imprecise, so don't match well the requirement to a rather precise over-voltage threshold.

Do you have an idea how to achieve such precise over-voltage protection (suppressing short transients, and cutting supply (blowing fuse?) for prolonged over-voltage)?

Cost doesn't matter (the equipment to be protected is likely to be at least 2 orders of magnitude more expensive than the components needed). Compactness is a plus.

EDIT :

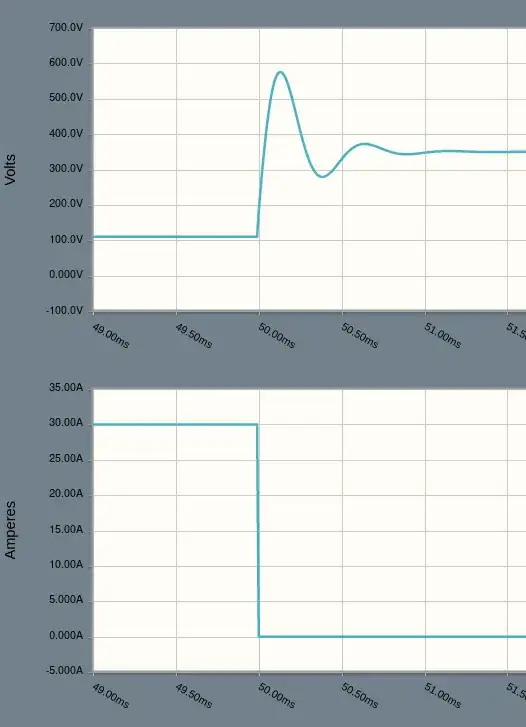

to get an order of magnitude for the transients, I did some simulations (nb : I decreased C1 by 2 orders of magnitude, otherwise, there is no overshoot at all)

So I think that a 600V spike for 300µs should be a good approximation of worst case. I would therefore aim for protecting against 1kV for at least 2ms without blowing a fuse.