As an alternative to Kapton or heatshrink, you could also wrap the bundle in PTFE tape - the same stuff plumbers use to wrap around pipe threads.

If you can wrap it around the wire tightly enough with significant overlap, it should hold itself together. Could be a rather fiddly task for a small wire bundle, but has the advantage of being very thin yet quite strong, and also lubricating as you pass the bundle through the various holes.

You could also just get some very thin walled flexible plastic tube, that is sized such that the internal volume is at most 60% filled (to make it easy to slide the wires bundle in).

This doesn't have to be heat-shrink tubing - in fact leaving the wires free to float in the tube may minimise risk of damage as you are bending it around because all the strain is taken up by the tubing not the wires.

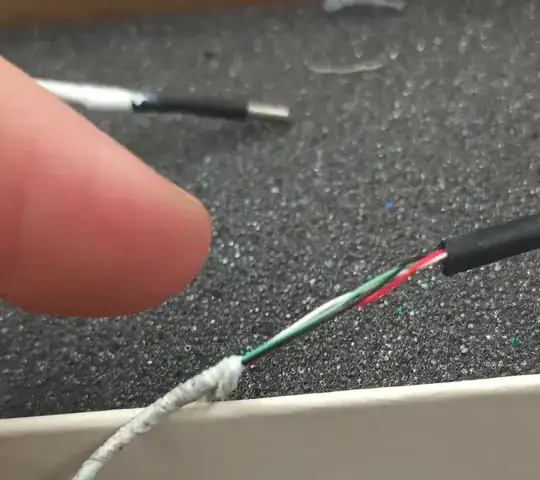

We have some pressure transducer catheters at work that use this exact technique - three very thin metre long enamelled wires inside a 2mm OD flexible tubing (I think PVC, but could be any number of things).