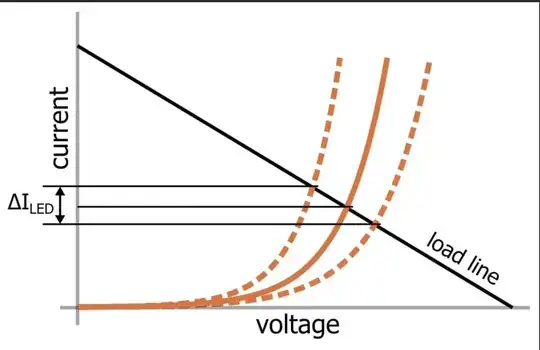

I have a bunch of LEDs. As I understand it, despite being the same part number, their behavior (in terms of brightness) can vary significantly.

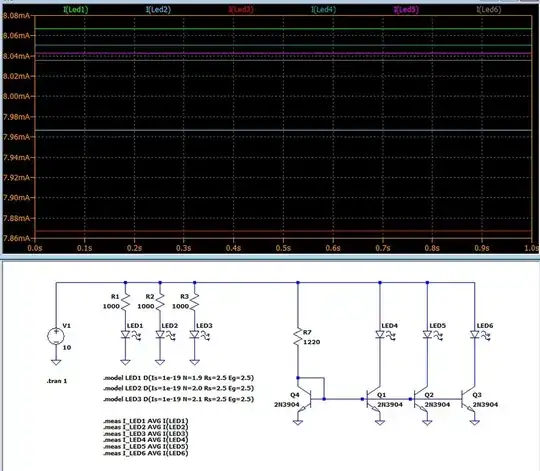

If I'm going to use a whole bunch and would like them to have similar brightness, and I can't drive them in series (e.g. an LED strip that can be cut between individual LEDs), is it better to use a 2-pin inline constant current regulator (e.g. as mentioned here), or a boring old resistor? More interestingly, please explain the trade-offs of each. (Obviously "price" is going to be one of those, but which behaves better in terms of brightness uniformity, and why?)

If there's a [performance] difference between a constant current regulator and a constant current diode, feel free to address both in an answer.

(Related to, but not the same as, How to wire mixed-count groups of LEDs?, which didn't get a satisfactory answer. Also similar to How to choose a perfect resistor to LEDs to get same brightness?, but the answers there have very little in the way of explanation. I don't just want to know "what works better", I want to know why it works.)

...and yes, I'm aware the "best" answer is to start with LEDs with similar performance in the first place. Best case, I can avoid that. Worst case, I do that anyway but still want to know how to best hedge my bets.