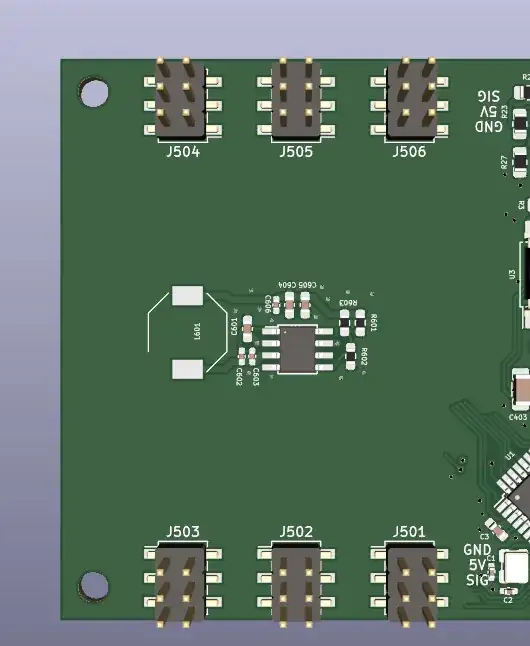

I have this unfinished PCB with 12 servo connectors and a buck converter circuit (the inductor has no 3D model yet.)

I want to prevent these RC hobby servos from moving at all when I power up this board. In order to do so I need to apply the PWM signal before the servo is powered by 5V. This prevents that small bump they usually do.

The software can retain the last known servo positions using EEPROM, so the controller knows for every servo what its PWM must be during power up. This should prevent the big bumps during power up.

So, in order: I want to load last known positions from EEPROM, set all 12 PWM signals and enable the power supply to the servos.

During run time the software will ensure that only one servo will be moving at the time, simply because there is time for that.

How can I safely power on all servos? I have 4 IO pins left. I was thinking to simply use a relay to engage all 12 at once, but imagine that for whatever reason all 12 servos are not in start position, the current draw may cause problems. The buck converter is rated to 2.5A

Can I solve this by just adding a bucket load of electrolytic capacitors?

The other thing I could think of was to use ancient ULN2803 chips, reduce the design to 8 servos and turn them on one at a time (or 2 at a time) I would switch the servo's ground pins with the ULN chips.

EDIT: In response to the comments: When a servo is in position, I kill the PWM signal to the motor.