I have a system composed of a video processing board connected to a 3-meter flexible endoscope. The endoscope cable has 10 signals (including ground) going to a sensor at the tip and an EEPROM (all low voltage 3.3V, low current 10mA). The sensor data rate is 8 MHz. The cable is shielded except for a small PCB in the middle of the flexible scope containing the EEPROM.

I'm having trouble with the Radiated Field Immunity test (IEC 61000-4-3). There's one part with a 10 V/m field ranging from 80MHz - 1GHz AM at 1kHz and a couple frequency ranges give me trouble (86 - 100MHz, around 360MHz). It varies a bit at different orientations of the antenna and DUT, but it's similar.

I was able to pass the test by attaching a ferrite core on the cable, but it's not ideal to add that to the cable since it's disposable (i.e. it increases cost, we already have a lot made), so I need to put this filter on the PCB. I'm not that experienced in PCB EMI filter design, but I know the basics. I definitely need to learn more.

My question is what is typically used for the EMI filter in a situation like this? I've looked at common-mode chokes, ferrite beads, pi filters. Common mode chokes are huge. A ferrite bead on each signal would be easiest, but I'm not sure if that would work since this is all common mode. How do I deal with ground?

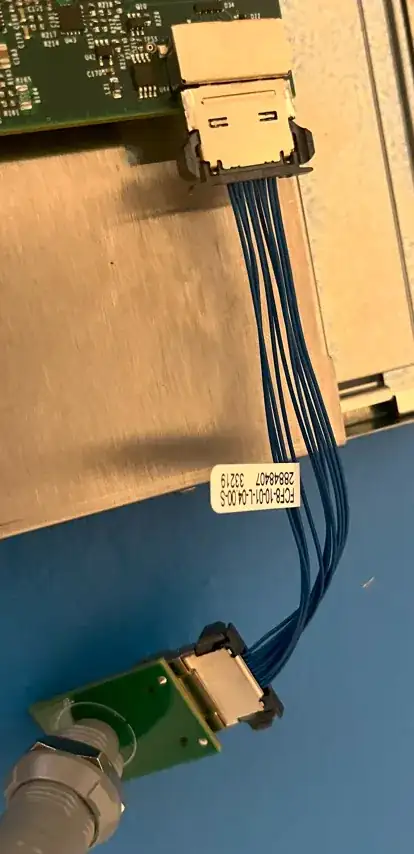

Luckily I have a small scope connector board in between the scope and VPU where I can put this filter.

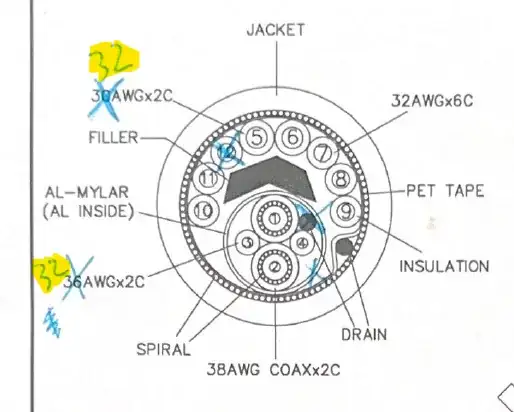

Here's a cross section of the cable (disregard the blue):

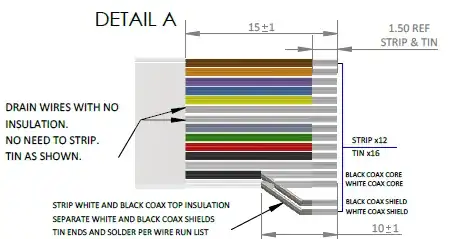

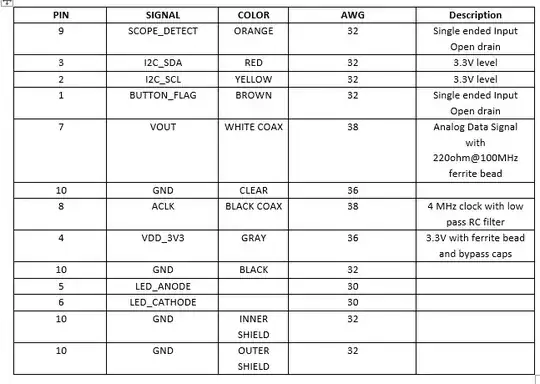

They're all single-ended signals:

Here's a picture of the connector and interface to the VPU (connector is panel mounted to the enclosure):