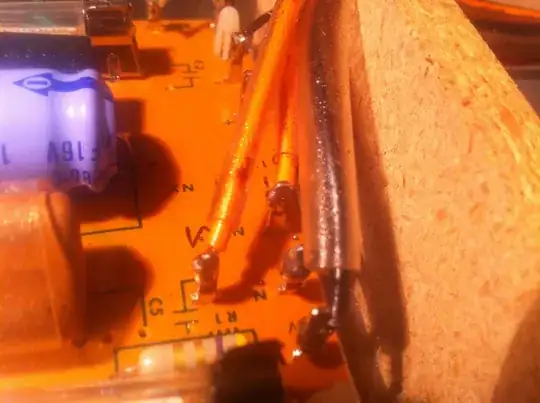

I would guess that the sleeving is for extra electrical insulation. I see in your photo that these wires are passing near the fuse holder, so they may be part of a secondary-side circuit and due to the physical construction of the turntable are forced to pass near / across the normal isolation barrier between primary and secondary.

For these sorts of things, I tend to look at it this way: if the original manufacturer went to the trouble / expense of putting sleeving on these wires, it's probably necessary, even if the reason may not be readily apparent.

If you want to replace the sleeving for aesthetics, I'd think twice. If the sleeving is starting to become brittle and break down, or is cracked, by all means replace it, or shore up the weak sections with several turns of electrical tape or Kapton tape. If you are really compelled to replace it, try and find similar thickness material that is appropriate for electrical insulation (e.g. PTFE / Teflon).

If you really must replace the wires and don't want to sleeve them, make sure that the wires you're using are at an absolute bare minimum rated to 600V insulation. (Don't use regular 150V or 300V appliance wire - get the good stuff.)

(Even with 600V wire, I'd still put sleeving on them. Yes, I'm paranoid, but I also do this sort of stuff for a living. I've seen many "interesting" dielecrtic breakdown failures during safety testing of the products I've developed, and have had to insulate things that I never thought were "insulatable.")