My question: Can I use it?

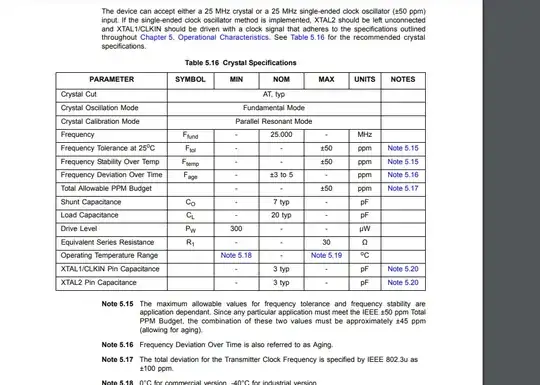

No, you can't because the LAN chip delivers higher power levels into the crystal to obtain better regulation at the oscillation frequency. Note that the chip specifies a loading capacitance of 20 pF and that means 40 pF each side of the crystal to ground and, the knock on effect of that is that frequency stability improves. Take a look at this picture to begin to understand why: -

What the picture shows is a typical 10 MHz crystal (20 Ω ESR) with various loading capacitances from 2 x 5 pF (net CL = 2.5 pF) to 2 x 40 pF (net CL = 20 pF). Of particular interest is the phase response of the crystal (the lower picture) because with 40 pF capacitors, the frequency is less ambiguous (the graph is steeper) as it passes through 180° phase.

This means that the crystal overall (in its oscillator circuit) will have less drift due to temperature effects on the silicon altering the frequency of its 180° phase-point. So the crystal produces 180° and the silicon (aka inverter) produces 180° and you get an oscillator.

The bottom line is that with higher CL you get better stability but you inevitably drive harder and that means more power dissipated in the ESR of the crystal. There is of course some danger that more power dissipation in the crystal can lead to crystal drive frequency changes but this will be smaller than the effects of the inverter used in the typical pierce oscillator circuit altering its propagation time with temperature. But it can be a trade-off.

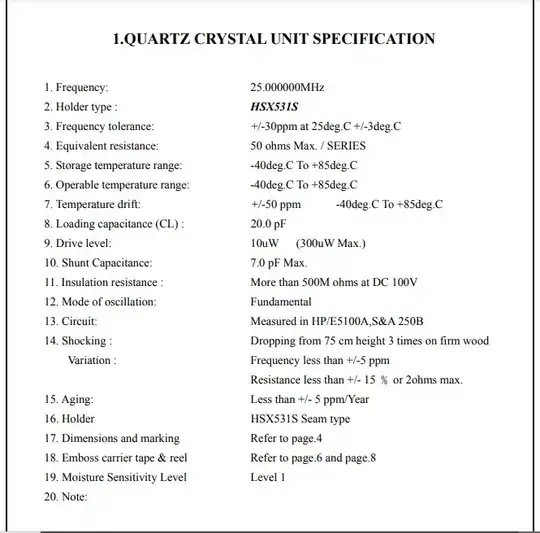

So, choose a crystal that can work with 2 x 40 pF loading (net = 20 pF) and can survive (without detriment) the power levels. In the example above, if the voltage drive level were 4 volts p-p, the power when CL = 20 pF would be around 300 μW.

Picture from here.