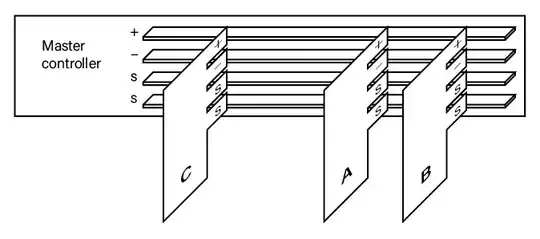

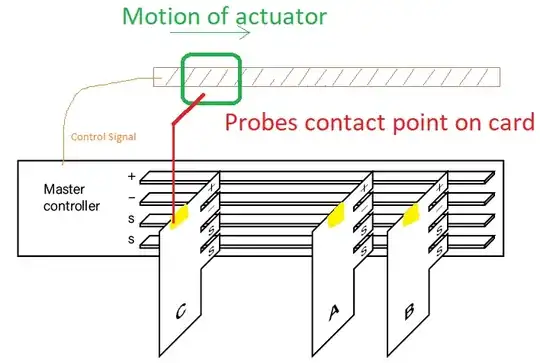

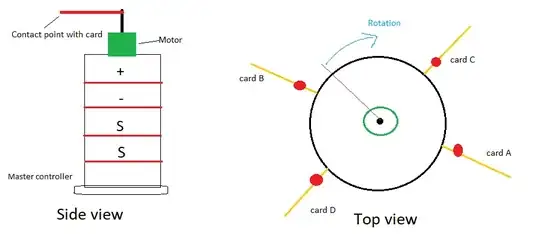

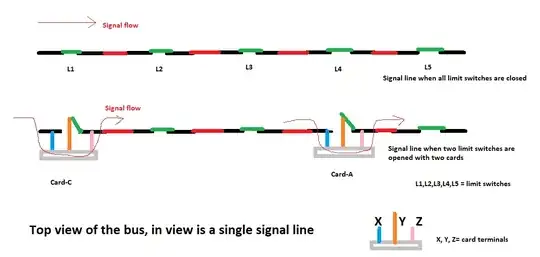

REVISED: I have a master controller PCB with four bus bars (+, -, and two signal lines), see image below. I have module PCBs A-C (or could be 10 or 15 of them), each with MCUs and unique identifiers, that plug into the sockets in an unknown order (and may or may not all be present). How could the module PCBs communicate with the master controller so that the master controller would know the ordering of the module PCBs. (In the digram it would be [C, A, B].) The two "signal" lines drawn could be reconfigured (or additional components/circuitry added).

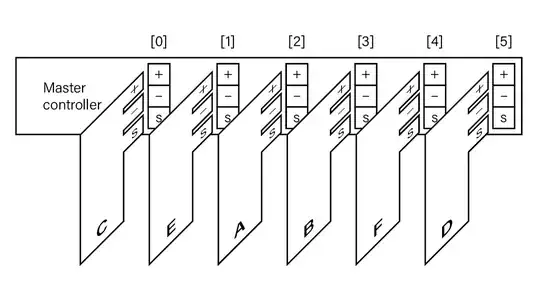

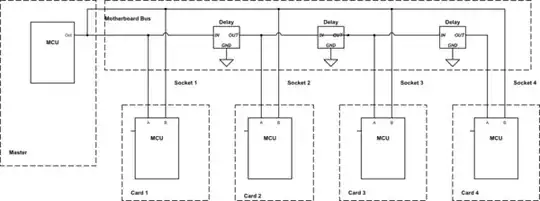

ORIGINAL: I have a master controller PCB with sockets 0-5. I have module PCBs A-F (these are also the unique IDs, either through an MCU or other means) that plug into the sockets in an unknown order (and may or may not all be present). I am wondering if there is a simple way for the master controller to know the ordering of the module PCBs. (In the digram it would be [C, E, A, B, F, D].) There is one "signal" line drawn but additional ones could be added (or additional components/circuitry).