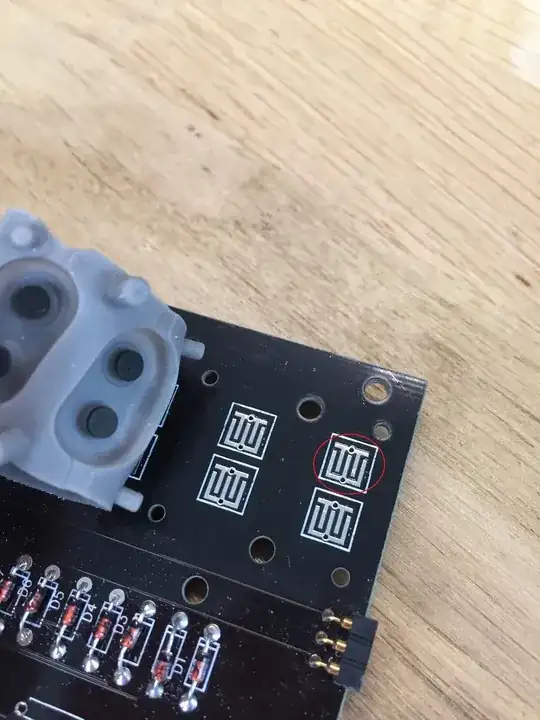

I have a question regarding PCB design and rubber keypad contacts. I did this circuit for prototyping a piano keybed but some contacts seem to be unstable: when pressed it switches from 0 to 1 continuously - this isn't a classical debounce issue but some kind of electrical instability. I know that it is best to use carbon ink, but it is way too expensive for a prototype.

My question is then: do you think my design of the pad could be the issue, or is this a pull-up resistor issue, or simply some dirt?

Thanks