From the Reference Design User's Guide, page 42:

"The meter constant is typically given in units of impulses per kilo-watt hour. As an

example, the calibration output frequency of CF, METER_CONSTANT =

3200 imp/kWh or 6400 imp/kWh"

Section 5.1.1 on page 41 describes the calibration procedure.

edit

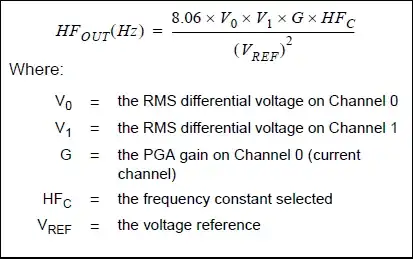

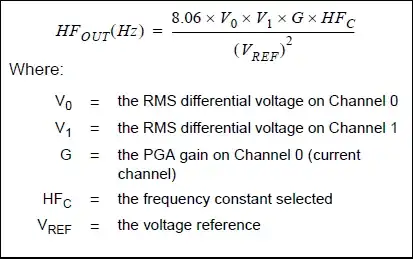

Also had a look at the datasheet, and on the same page 20 Mike refers to there's this equation:

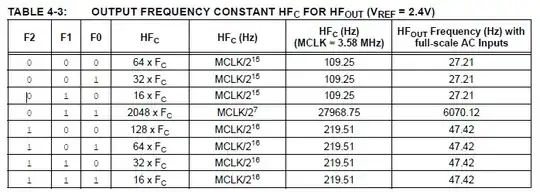

Channel 1 is the voltage sense channel, channel 0 is the current sense. Multiplied, including the current sense amplification you get instantaneous power. Input voltages are converted relative to a reference voltage, so you have to divide both channels by that (the denominator). HFc is a constant you can program by setting F0, F1 and F2, as per the table in Mike's answer (page 20 of the datasheet).

Note that this gives you a frequency proportional to power. Integrating this over time means counting periods of that frequency gives you a measure of consumed energy, and that's where the 3200 imp/kWh from the Reference Design User's Guide comes in.

edit

A concrete example. Let's suppose you want to measure energy of a 230 V/ 10 A device. Maximum input for the voltage channel is 660 mV, so we choose a 1:1000 divider for that. At a gain of 1 for the current channel maximum input voltage is 470 mV, so we can choose a 10 mΩ shunt for that, which gives us 10 mV/A. We use the internal Vref of 2.4 V, and set F0, F1 and F2 to 0. Then for a 230 V/ 10 A input we get

\$ HF_{OUT} = \dfrac{8.06 \times 230 mV \times 100 mV \times 1 \times 109.25 Hz}{(2.4 V)^2} = 3.516 Hz \$

That's for 2300 W, or 1.529 Hz per kW. For 1 kWh we'll have

\$ \text{pulse count} = 3600 s \times 1.529 Hz = 5503 \$

That's 5503 pulses/kWh.

so this will mean 152 imp /kwh :D , I really need this point & thanks from here to tomorrow

– xsari3x Jul 11 '12 at 17:30thanks a lot :))) depending on my hardware I will determine the imp/kwh :) – xsari3x Jul 11 '12 at 18:12