If you have trouble understanding what terms like 'current', 'series', and 'parallel' mean -- or have trouble understanding these diagrams -- I recommend trying out Khan Academy's excellent electrical engineering series. And no, I'm not being payed to say that. It's totally free.

Well, the first question is, do you really need 10?

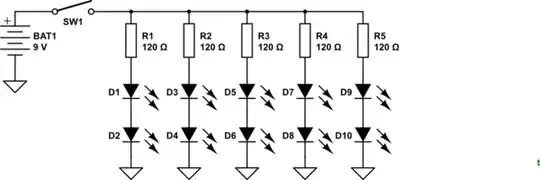

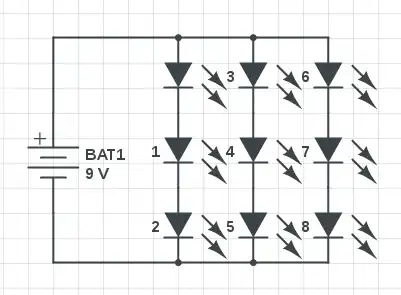

I actually did something similar to this to make a little flashlight circuit recently, using a 9v battery and a matrix of nine 3v 30mA LEDs connecting like so:

The thing to remember, here, is that connecting things in series means the current thru them is the same, but the voltage drops. Connecting things in parallel means the opposite -- voltage is the same, but current drops.

So in circuit 1, we see that we have 3 strips of 3 LEDs, for a total of nine. Each strip is connected in parallel, so the voltage across each strip is the same as the battery (9 volts). The current is triple what we'd have for a single strip of LEDs, but is still tiny, and well within what the battery can supply (~90 mA).

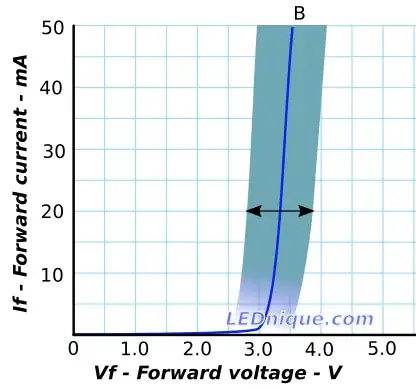

LEDs that function best at 3.2 volts can probably function at 3 volts, so this circuit should achieve close to maximum brightness with no power wasted on resistors.

Edit: It's notable that this design might have cascading failures over a number of possible things. If any one LED fails open circuit, one string will fail, and the current across the other 2 strings will increase. Conversely, if it fails closed circuit, it will put more voltage across the other two in the LED string, also potentially causing a cascading failure. This is all useful information, but this seems like an entirely acceptable product design as long as you consider what it means for the LEDs to fail. Your circuit should be prepared for the possibility that the entire cluster of LEDs becomes a dead short, and shouldn't catch anything on fire (fuses, anyone?).

Furthermore, if longevity and reliability is your priority, you might be better off using Transistor's schematic, baring in mind that you will waste a rather significant percentage of battery power. Or better yet, use a buck converter module. But all of these options, it seems to me, are out of the scope of OP's goal -- which was decidedly not to make a final product design for a company that needs to be UL listed.

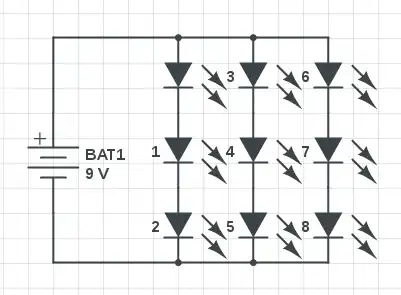

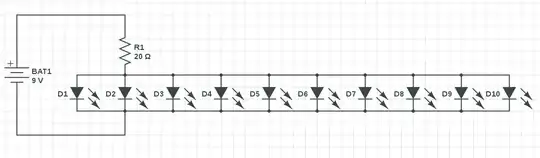

If you need 10, this design doesn't work of course. One option is to do something like this:

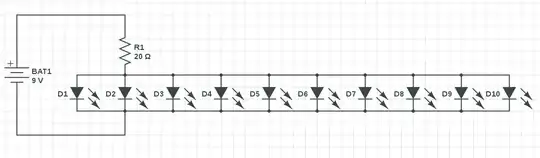

Which one person already suggested. This would work, but generally speaking, the less voltage you have to drop across a resistor, the better. I'd recommend something more like this:

As you can see, we are dropping 6 volts across the LEDs, and are left with only an extra 3 to drop across the resistor. We know each LED takes 30 mA, so the total for each string of LEDs is also 30 mA (0.03 amps), since series of components have the same amps. Each string is connected in parallel, and we have 5 strings, so the expected total for the LED matrix is .15 mA. We can calculate the value of resistor to use, with ohm's law, like so:

Voltage (V) = Current (I) * Resistance (R)

V = IR

V/I = R

3 v / 0.15 amps = 20 ohms

Edit: I did a bit more calculating, and the resistor from this diagram, that I suggested you use dissipating .45 watts (0.15 * 3 = .45). Thus, I suggest you use at least a 1 watt resistor. There are also ways to use multiple smaller resistors as one larger one, to spread the heat out.

Edit 2: As Transistor pointed out in their answer, you can also split the resistor up into multiple resistors for each. The efficiency of this is exactly the same (about half a watt dissipated by the resistors in total), but it is actually considered somewhat better practice to split your heat across your circuit, rather than just using a bigger resistor. I mainly try to go for minimum component count in my designs, but you might be better going with Transistor's design if you want better longevity.

Addendum: as one person pointed out, Transistor's circuit also is more reliable if there are wildly varying electrical characteristics of the LEDs -- if one string pulls more current, the other ones will be affected, with my single-resistor circuit. So if you're going to use a resistor-mediated circuit, theirs is probably objectively best (in terms of reliability).