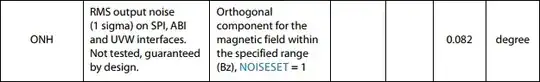

I am using a magnet encoder chip AS5147 and I chose to use SPI to read the output position of a gearbox connected to a motor. The position resolution is claimed to be 14-bit when using SPI reading. A button magnet was mounted on the output gear shaft with a plastic holder, and the sensor was mounted on a PCB and the sensor alignment and distance from the magnet was carefully adjusted according to the spec. When the motor was at standstill and I read the position value using SPI command, however, the value was not stable at all. The value variation is about 3bit, which actually made it to be 11bit encoder.

What I want to ask is, if anyone has ever used such magnet encoder before and is it actually so unstable in position reading? Or is it because the alignment or sensor distance from the magnet was not well adjusted?