I know next to nothing about electronics, so treat me accordingly :D

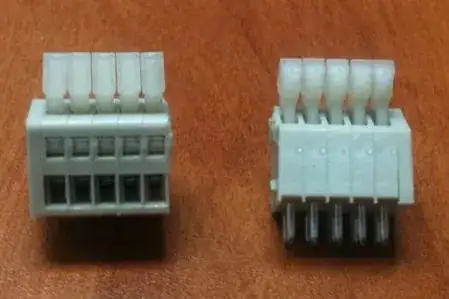

I have these terminal blocks:

To the best of my understanding, wires go in, and the levers clamp down to hold the wires in the place.

1) The levers are really stiff. Am I supposed to be able to flick them with my bare hands?

2) The wires go in the holes on the bottom as seen in the left-hand block, right?

3) Why are there two rows of pins?

4) If I want to connect these blocks together, do I have to pry off that excess plastic piece on the side?

Thanks very much :D

EDIT: Turns out you push down the levers to open the hole, and then they spring back to keep the wire in. The levers are really stiff, but I think they get a little easier to use after pressing them a few times.