In my circuit I'm using an assembled LM2596 converter module (those which are like $2 on ebay). The input voltage is 26V AC (current 140mA), which is rectified (making it ~36 peak DC), and feeds the buck converter. The output is 5V DC, 600mA. All seem to be within reasonable ranges for the converter, but it overheats pretty fast to the point I can't touch it anymore. And if left overnight for testing, it burns out. Both the LM2596 chip and the 330 induction heat up; the inductor seems to be hotter.

So far I tried to drop the voltage at the converter by inserting the capacitor (up to 100mF, non-polarized) into the AC circuit for capacitive resistance. This drops the input voltage to ~9V but the capacitor itself overheats really fast. I also tried with different modules, and they all do the same.

My questions here:

- Is it normal?

- If yes, what could I do? Is it reasonable to chain the converters, like using the first buck to drop something like 36 -> 20, and then the next one to drop 20 -> 5? Any side effects, besides the cost of two converters? Or is it more effective to put them in parallel?

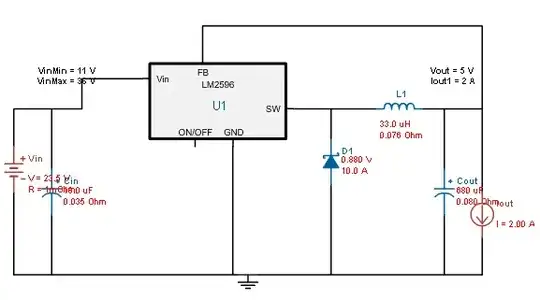

Edit: photo of the module. The dark chip says LM2596 -ADJ:

Conclusion: I have tried a bigger capacitor (2200uF), a different inductor, and a heatsink. Nothing worked, except stacking regulators.