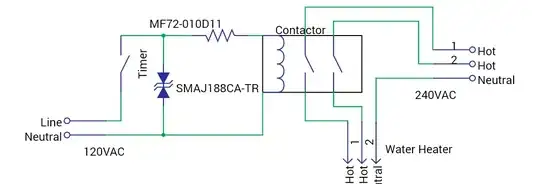

I built a timer for my water heater and have a question about spark suppression. I am using a 120v house timer 1875W to operate a Packard (240B) 2 pole 40A 120v coil relay. The output of the relay contacts are connected to 240v that goes to the water heater element. It worked for about 3 months and then the relay does not release because I think the timer contacts are fused together supplying constant ac to the rly. coil. I think that I may need a spark suppressor across the input of the 120v input of the relay coil. I was thinking about a RC network but I don't know what type of cap and resistor values are needed. I have a drawing but I don't know how to upload it to this post.

Thanks, doogdoog