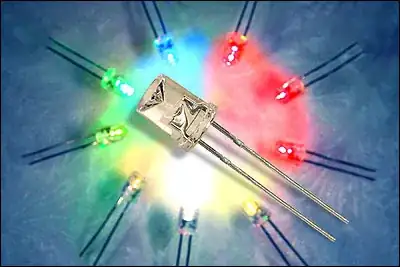

LEDs with a concave cone-shaped lens are sometimes called "straw hat" LEDs. What is the advantage compared to the more common hemispherical lens?

LEDs with a concave cone-shaped lens are sometimes called "straw hat" LEDs. What is the advantage compared to the more common hemispherical lens?

The straw hat LED lenses have a much more even light distribution pattern than the typical hemisphere lens. The hemisphere lens usually focus the light into a narrow cone of maybe 20 or so degrees. One application that workes very well is Christmas tree lights. The straw hat lenses make the LED disperse light like an incandescent bulb.

"Straw hat" LED is the name generally given to LEDs whose envelope is shorter and wider and flatter than the typical 5mm epoxy LED. The main feature is that a very wide radiation angle is achieved - typically 90 degrees to 160 degrees full cone angle.

HOWEVER, this is NOT what you described in your question and nobody (as of January 21st 2013) has actually answered what you asked.

Most LEDs use a formed lens as part of the construction.

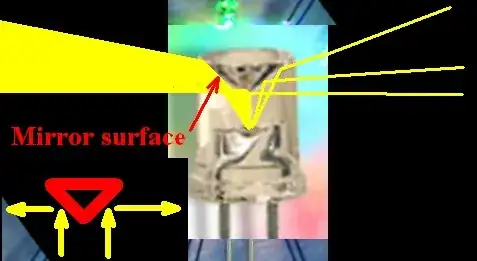

The LED that you are referring to does not mainly use a lens - instead it uses an internal reflector - see diagram below.

With the LED aligned to radiate vertically (as shown) the light from the die travels vertically at a relatively wide angle and encounters a mirror surface and is reflected almost horizontally. As the light rays from the die are not parallel they will intersect the mirror at differing angles depending on source and destination so the light will be spread in a vey wide angle band or halo. There is NO direct frontal radiation as the mirror assembly is opaque. There may be some forward radiation at all angles due to internal reflection in the LED body but the level will be low.

Why do this? / What is it used for?

If you place this LED in a larger external reflector it will place most of the light on the reflector surface at a short distance beyond the LED. So a very short reflector can do a good job or forming the beam into some other forward pattern.

I have seen high power LED torches designed for Police use. These had standard wide angle SMD LEDs and deep reflectors, but the very large majority of the light was handled by the region just beyond the LED.

There seems to be a discussion about what a straw hat should look like.

Both are straw hats, but the left one is concave, while the right one is convex. Searching images.google.com returns almost exclusively LEDs which are convex shaped:

While the classic PTH LEDs are more like "Elbonian hat", these have their die closer to the lens, and the lens is also less rounded. This makes for a much wider radiation angle, typically 120° to 140°, whereas the Elbonian LEDs often have radiation angles less than 60°.

I'm one of the two inventors of the Straw Hat.. When early high brightness Nichia white LEDs came out, my friend John Mize started a company to make LED flashlights using T1-3/4s sized LEDS. We needed a way to force the

light to fill the reflector of the flashlight. John was not a Optics person, and asked me to help with getting a nearly collimated beam for his flashlights.

We started with a standard LED and built a rig to grind a new curve onto the stock led surface. By careful use of a balance between Total Internal Reflection, Scattering from the grinding, and Forward Emission, we could get a reasonably nice beam in a standard flashlight reflector intended for a two "D" cell flashlamp. I'm the one who taught John about TIR. My name does not appear in the patent as I did the contract work.

The LED with the Conical Pit is a patented design by a fellow named YAN. Yan's device was cited against us in the patent review stage by the examiner. We had to submit a reply showing a goniometer scan of the beam patterns. Ours showed considerable improvement over a stock "YAN" device or the patent would have been rejected.

When John's major licensee insisted on shifting production to Hong Kong, the design was readily copied where there was no patent enforcement, and someone paid to have molds made for the shape.

It has since been widely copied and modified.

See US 6328456, John v. Mize..

The phrasing and image of the original question are in conflict: the image shows not "straw hat" (a.k.a. "helmet") lensed LEDs, but "concave cone" or "inverted cone" lensed LEDs. Stevenh's reply shows a "straw hat" lensed LED.

The purpose for both of these alternate lens shapes has already been mentioned: to change the light dispersion pattern. A standard round-topped LED typically throws a bright cone with a vertex angle in the range of about 20 to 90 degrees depending upon the specific geometry used (or, for diffused types, is most brightly visible from angles in such a range).

A straw-hat lens projects a broader more-or-less even hemispherical pattern, which again depending upon the exact geometry may approach or exceed 120 degrees.

However, the description given by Russell McMahon for the inverted cone lens is not quite accurate - the inverted cone is not an opaque reflector. So, while this design does project the majority of the light in a slightly forward-angled band as shown in the diagram, a significant amount of light still goes through the cone in the more generally forward directions. This also results in a more-or-less hemispherical projection pattern, but with brighter light toward the periphery and some unevenness characterized by brighter and darker rings in the pattern, compared to the straw hat pattern which is more even overall, generally does not have any noteworthy bright rings in the forward direction, and is usually somewhat brighter toward the center straight-ahead direction.

LED Shapes:

"Bullet" - (traditional type) gives spotlight beam for flashlights

"Strawhat" - (shorter lens) gives wider floodlight beam

"Flat Top" - (as it says) gives wide spread light

"Inverted Cone" (shown in original question) - gives sideways light all round, but less to the front