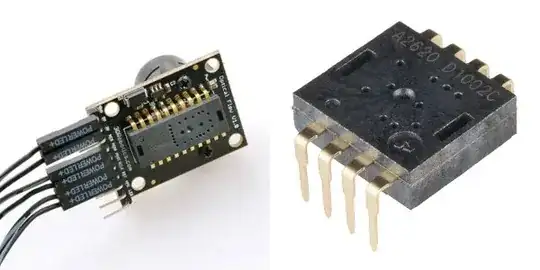

Almost certainly alignment pin holes from the injection moulding machine.

They will be used to keep the internal leadframe sections in the correct position when the casing is moulded so that the IC can be placed in the final place and bonded to the leads inside the case.

Most ICs are assembled on the leadframe while it still has metal bridging the pins and they are cut away after encapsulation moulding so the leadframe alignment is not disturbed during moulding.

These devices likely use a somewhat different moulding process as they have to keep the bonding pad locations free of plastic and in the right place to allow for wire bonding after IC attachment.

Another thought occured to me that may be equally relevant, they may be used to hold anvils (a bunch of tapered flat topped pins) during the ultrasonic wire bonding process so it makes a reliable bond when otherwise the plastic case would have to provide the counterforce which may be inadequate in practice.