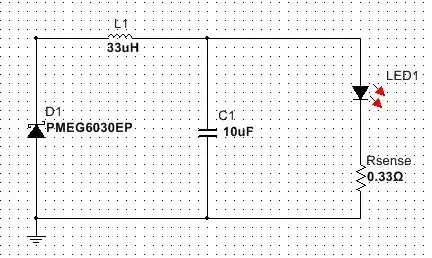

I'm building LED driver based on current mode control buck converter. My question is quit general. If load is disconnected then output capacitor voltage shoots up. If load is reconnected it gets overcurrent spike from that charged capacitor. If output capacitor cannot be removed, what else can be done? Is there a general approach to this problem?

Thats a simplified circuit. If LED is disconnected, output capacitor charges to high voltages and can destruct the LED if it is reconnected.

My biggest worry is if I'm missing something simple and obvious? If not, thats ok, I will do my work somehow.