I'm preparing for a seminar related to variable gain amplifier. I read that GaN/AlGaN are used. I wish to know why they specifically use them.

-

Since you haven't told us what devices will be discussed, there is no way to answer your question. Try reading this http://www.ti.com/lit/wp/slyy071/slyy071.pdf – WhatRoughBeast May 31 '15 at 17:12

2 Answers

There are a number of properties that one would wish from a power electronic device:

- Voltage withstand capability

- Speed of switching

- On-state losses

- Thermal capability

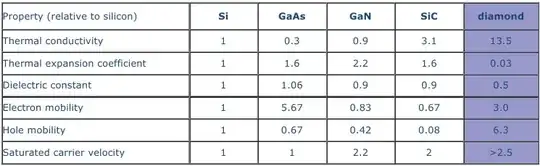

If you look at all the materials that possess semiconducting properties diamond is at the top. The problem is how to get there. Germanium was the 1st material used to create a semiconducting device and as crystal growth tech and doping tech progressed, Silicon became a possibility.

We are now in an annoying place. We have the technology to grow Silicon Carbide crystals BUT the yield is low, really low but we have also reach a point where we cannot realise an increase in power density via silicon alone.

Gallium Nitride is a stepping stone until SiC process improvements are realised. Equally there is only a couple of switching types that have been successfully doped and even then they are at low current -> low power.

- 5,791

- 6

- 23

- 40

-

2With regards to GaN being a stepping stone to SiC, I must respectfully disagree. SiC has lower mobility, lower $v_{sat}$, and something you didn't mention, lower bandgap energy $E_G$. Higher $E_G$ permits a higher breakdown field $E_{CRIT}$, so a GaN device with the same $R_{ON}$ and physical size can withstand more volts. GaN is a superior crystal for power switches; the main things holding it back are low yield, incompatibility with high-temp processing and the lack of a quality oxide. – Zulu Jun 01 '15 at 04:13

-

Ok steppingstone was probably the wrong term as for alot of things it is end-tech (until something new comes along - diamond). SiC advantage over GaN is the withstand voltage and that is something you want from power electronics. Sure 600V GaN switches are fine for 1ph 230V (Europe) or 3ph 115V but 400Vac with a DClink of 540V... you need 1200V devices and the future for that is in SiC. This is before bringing in higher voltage devices – Jun 01 '15 at 07:58

-

I'm no expert, it seems like GaN is fundamentally better than SiC for voltage standoff; my understanding is, most modern GaN devices can't make it up there because their crystal defect density is too high (they grow GaN on a silicon substrate to reduce cost, but the different lattice constant causes dislocations). But check out Avogy. They use GaN substrates to reduce the defect density, and claim 1200V FETs. Seems to be the way to go. – Zulu Jun 01 '15 at 16:07

-

As I understand it, SiC devices have a vertical construct which lends itself to higher voltage operation. Whenever I speak to Raytheon or microsemi they push GaN and SiC for different applications with a clear split around working voltage. Maybe its a process limitation at the moment but right now that's how it appears to be marketed – Jun 01 '15 at 17:05

-

Indeed when GaN is grown on Silicon, the device is by necessity a lateral device. When comparing one compound to another, it makes it a little unfair: comparing lateral GaN to vertical SiC. Avogy, however, claims to make vertical GaN devices. At this point the barrier to greater adoption seems to be the business case and technology maturity, not the semiconductor compound. – Zulu Jun 01 '15 at 17:12

-

Silicon Carbide does not have low yield. Many companies are in high volume production of (650V->6kV) FETs and Diodes such as GE, Fuji Electric, Infineon, United Silicon Carbide and Cree, just to name a few. High Voltage GaN on silicon is also high yield, and in production by many companies such as Transphorm, TSMC (foundry) and Panasonic. The real question is what material is best suited to the system that it is going into. For higher frequency switching, GaN wins and these tend to be systems under 5kW. For higher voltages, SiC wins and these systems go from 1kW to 100kW or more. Below 1kW Silicon, Super junctions and diodes are continuing to improve and are the lowest cost choice.

- 51

- 1

- 1