No, I'm not asking you about my whole design - just one little bit of it.

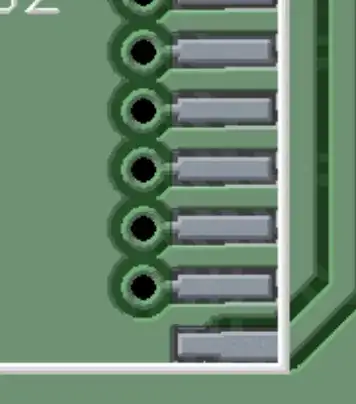

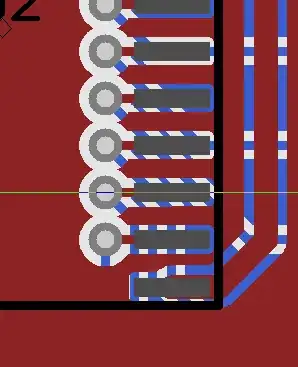

I have SMT devices, and I am currently pushing 8 pins on each side of some chips (SO24) straight through to the other side of the board with vias:

Having so many vias so close together - is it really a good idea?

Should I be staggering them more, or spacing them out a bit? Will this make the board too weak? The board itself is designed to be plugged in and out of breadboard many times, so may be stressed quite a bit.

Btw - same area as it would look after fabrication: