I'm working on a design with MOSFETs and with the LT4415 device.

The MOSFETs should dissipate an average heat of 0.45 W (with peak at 2 W but just a couple of seconds with several minutes to recover). For the LT4415, the maximum would be 1 W of dissipation (but that should be much smaller 0.2 W , I will measure it during real use, it is hard to predict for now).

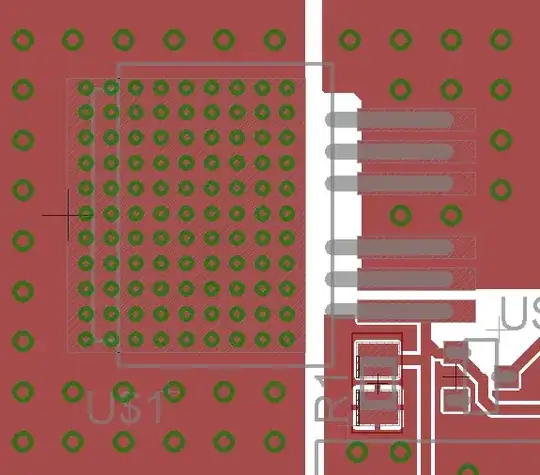

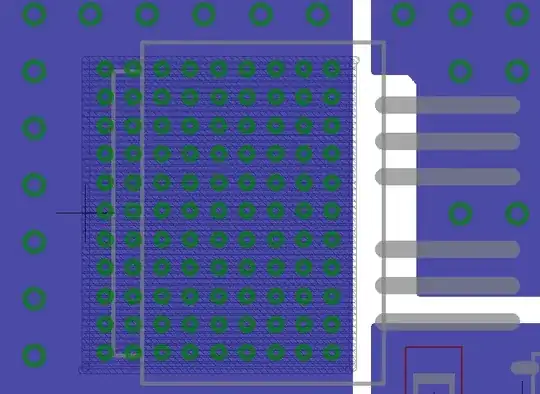

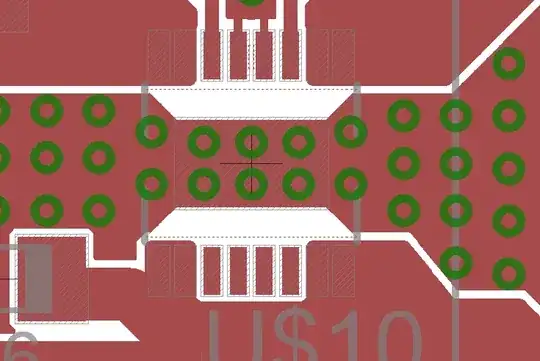

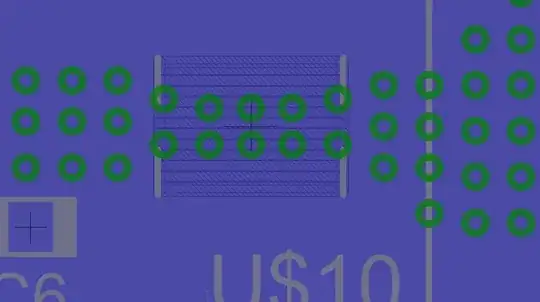

I decided to have a pattern of small vias (drill 0.3 mm) on a grid of 1x1 mm2. (I talked already about it in another question.)

Now my actual question is how to choose the type of vias. I can imagine that depends how I will solder the device. For now, I think I will solder them with solder paste and hot air.

Initially, my goal was to use filled vias. I talked with the manufacturer. Like expected, the price is twice higher and that takes much longer to manufacture the board.

So I'm wondering if it is a really bad practice not to fill the vias or to have them plugged. I can understand that vias filled with copper are better for heat conduction than empty vias or vias filled with epoxy. However, does that make sense to try or that doesn't have any chance to work out ?

My guess is that vias will be filled with solder so they may have a decent heat conduction, right ?

I attached some pictures of the design (red = top layer, blue = bottom layer, the hashed area are the respective tstop and bstop layers). Feel free to comment ! Thank you in advance.