I broke this up into two different questions.

1. Is it technically possible to get 110V AC by splitting a three-phase 220V AC system?

The answer to question one is "Yes". It's perfectly possible. Every other 110V circuit in your house is powered by splitting this same three-phase 220V AC into sub-circuits. If you look at your panel, the circuit breakers are arrayed like this (Yay for ASCII art!)

Leg 1 Leg 2

|------- |

| -------|

|------- |

| -------|

|------- |

| -------|

|------- |

| -------|

A 220V circuit simply bridges two of those breaker spaces. A 110V circuit uses just one of them. You're proposing to do this in a separate location.

2. Are there any problems with splitting a three-phase 220V AC system?

The only safety issue that I can foresee is that a short circuit in your 110V automatic drain valve wiring may not trigger the circuit breaker properly. I'm not familiar with how a 220V breaker works, but you're using it in a non-standard way: it will be loaded unevenly. It's entirely possible for one leg of the 220V line to become shorted and not the other, so the designers of the breaker should have planned for this.

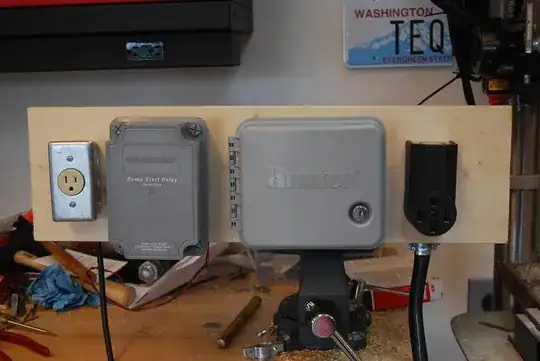

The other issue which hasn't been mentioned yet is the legal issue. You'll need to talk to an inspector or electrician to verify whether this procedure is legal or not. My copy of Wiring Simplified (which is a great resource for a DIY electrician, but doesn't cover edge cases like this very well) doesn't mention it, but you can read the National Electrical Code online for free and see if there's anything about that question. My guess is that they'll want you to run a sub-panel into your garage, and use separate breakers for your 220V compressor and your 110V automatic drain valve. That's significantly more expensive than an extra outlet in the attic, but it might be worth it to be compliant with the code and to not have to trek through the house every time you blow a circuit in the garage...

One last thing: Why do you need to turn the automatic drain valve off when you shut down the compressor? Depending on the valve you are using, the energy savings will probably be less than the cost of the extra outlet, and it will certainly be less than the cost of a failed inspection! Alternatively, you could use a float-controlled drain valve, which doesn't require electricity. There are other ways to do this!